Blog

The Integration of PEB and RCC in Modern Construction

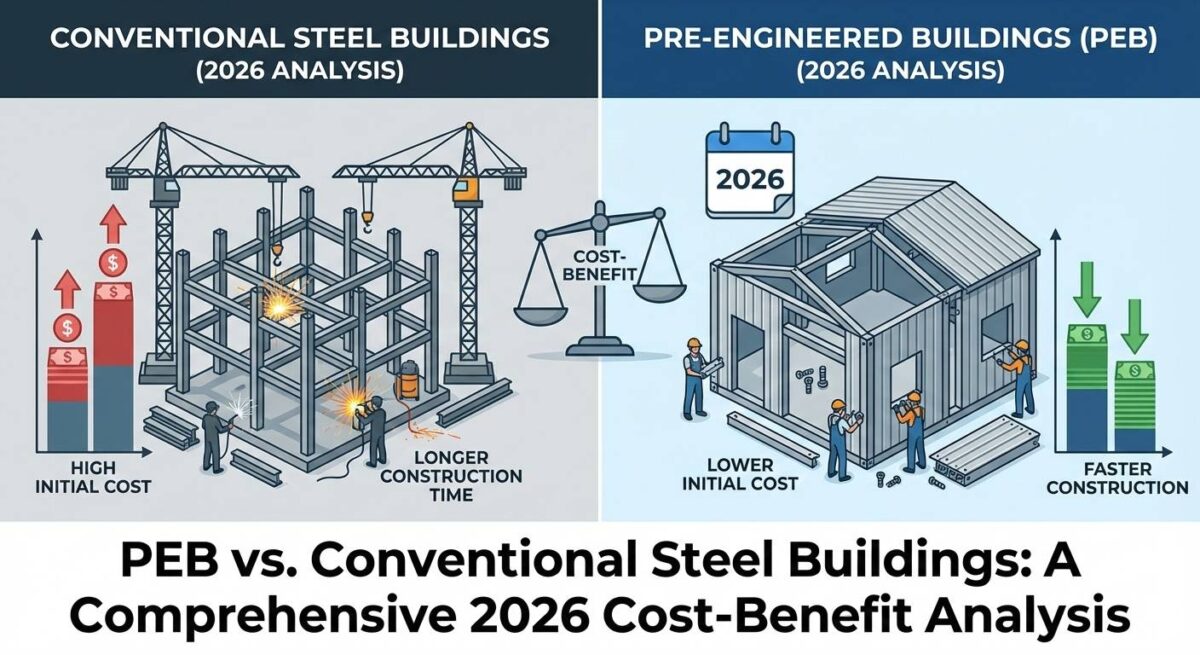

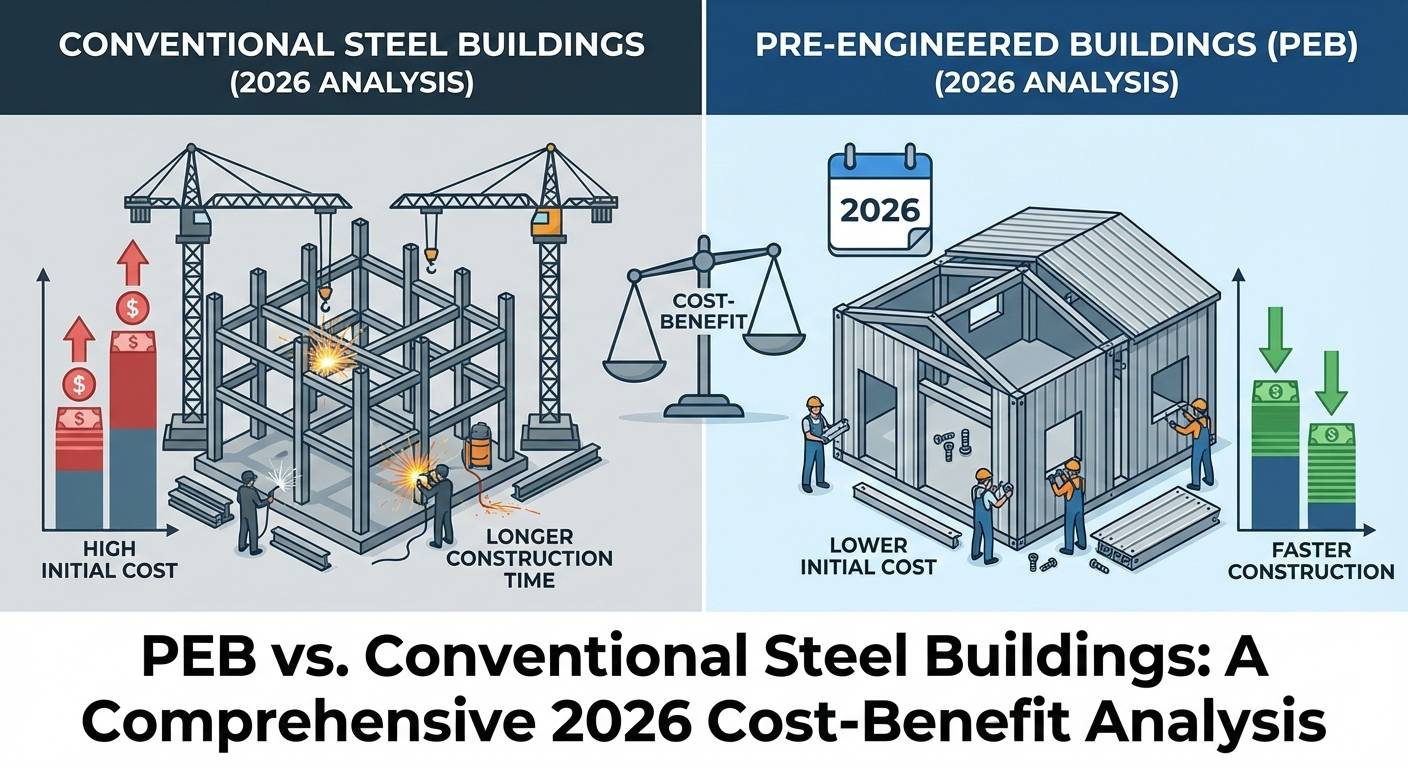

As India’s construction sector evolves, steel structures are increasingly replacing traditional RCC-only systems—especially in industrial, commercial, and large-span projects. However, a critical question continues to shape design decisions:

Should one choose Pre-Engineered Buildings (PEB) or Conventional Steel Buildings?

This decision is not only about initial cost but also about long-term performance, construction speed, adaptability, and lifecycle economics. In 2026, with rising material prices, stricter regulations, and sustainability goals, understanding the true cost-benefit difference is more important than ever.

At Rakhra Associates – Structural Engineers in Chandigarh, this blog is written to create awareness, clarify misconceptions, and help stakeholders understand how each system performs under real-world conditions.

Understanding the Two Systems

A PEB is a steel structure designed using optimized software, where most components are:

- Factory-fabricated

- Standardized and modular

- Designed for minimal material usage

Key features:

- Tapered built-up sections

- Bolted site connections

- Lightweight roofing systems

What Is a Conventional Steel Building?

A conventional steel structure is typically:

- Designed using hot-rolled steel sections

- Fabricated based on manual or semi-optimized calculations

- Welded extensively on site

Key features:

- Uniform section sizes

- Higher steel consumption

- Greater on-site fabrication

Design Philosophy: Optimization vs Flexibility

| Aspect | PEB | Conventional Steel |

| Design Approach | Software-optimized | Engineer-driven |

| Section Usage | Variable (tapered) | Uniform |

| Overdesign | Minimal | Common |

| Design Speed | Faster | Slower |

PEB systems are highly optimized for standard loads, while conventional steel offers greater flexibility for irregular structures.

Cost Comparison: 2026 Perspective

1. Material Cost

- PEB uses 15–30% less steel due to tapered members

- Conventional steel often uses heavier sections

✅ Advantage: PEB

2. Fabrication Cost

- PEB components are machine-fabricated with precision

- Conventional steel requires manual welding and cutting

✅ Advantage: PEB

3. Transportation Cost

- PEB components are lighter and compact

- Conventional steel increases logistics costs

✅ Advantage: PEB

4. Erection & Labor Cost

- PEB structures use bolted connections and faster assembly

- Conventional steel involves extensive site welding

✅ Advantage: PEB

5. Foundation Cost

- PEB structures exert lower dead load

- Conventional steel requires heavier foundations

✅ Advantage: PEB

Construction Time Comparison

| Stage | PEB | Conventional Steel |

| Design | Faster | Moderate |

| Fabrication | Parallel with site work | Sequential |

| Erection | Rapid | Slower |

| Total Time | 30–40% less | Longer |

Time savings directly translate into financial savings, especially for commercial projects.

Structural Performance Comparison

Load Behavior

- PEB performs efficiently under gravity and wind loads

- Conventional steel handles complex loads better

Seismic Performance

- Both systems perform well if designed correctly

- Conventional steel allows easier customization in high seismic zones

Neither system is inherently unsafe—engineering quality defines performance.

Maintenance and Lifecycle Cost

PEB

- Factory-applied coatings

- Lower corrosion risk

- Predictable maintenance

Conventional Steel

- Site-applied coatings

- Higher dependency on workmanship

- Slightly higher long-term maintenance

✅ Advantage: PEB

Architectural Flexibility

| Requirement | Better Choice |

| Large clear spans | PEB |

| Complex geometry | Conventional Steel |

| Future expansion | PEB |

| Heavy equipment loads | Conventional Steel |

Sustainability & Environmental Impact (2026 Focus)

PEB systems align better with:

- Reduced material wastage

- Lower embodied carbon

- Faster construction = reduced site emissions

With India moving toward green building norms, PEB adoption is increasing.

Where Conventional Steel Still Makes Sense

Despite PEB’s advantages, conventional steel is preferred for:

- Irregular architectural designs

- Heavy industrial plants

- Bridge components

- Structures requiring frequent modifications

Common Myths Explained

- ❌ “PEB is only for sheds”

- ❌ “Conventional steel is outdated”

- ❌ “PEB cannot handle seismic loads”

All are misconceptions. Engineering design, not system type, determines safety.

Role of Structural Engineers in Decision-Making

Structural engineers assess:

- Load requirements

- Span and height

- Usage and occupancy

- Seismic zone

- Budget and timeline

At Rakhra Associates, the focus remains on choosing the right system—not the popular one.

FAQs: PEB vs Conventional Steel Buildings

1. What is the main difference between PEB and conventional steel buildings?

PEB is optimized and prefabricated, while conventional steel is more customizable.

2. Which is cheaper in 2026?

PEB is generally more cost-effective overall.

3. Is PEB suitable for multi-storey buildings?

Yes, especially when combined with RCC cores.

4. Which system is faster to construct?

PEB.

5. Are PEB buildings durable?

Yes, with proper coatings and maintenance.

6. Can conventional steel handle higher loads?

Yes, especially for complex industrial structures.

7. Which system is better for seismic zones?

Both, when properly designed.

8. Is PEB environmentally friendly?

Yes, due to reduced steel usage.

9. Does PEB limit architectural creativity?

To some extent, compared to conventional steel.

10. What is the lifespan of a PEB structure?

Comparable to conventional steel structures.

11. Are PEB structures fire resistant?

Fire resistance depends on protection systems.

12. Which requires more maintenance?

Conventional steel generally requires more.

13. Can PEB structures be expanded later?

Yes, very easily.

14. Is conventional steel obsolete?

No, it remains essential for specialized projects.

15. Which system needs heavier foundations?

Conventional steel.

16. Is fabrication quality better in PEB?

Yes, due to controlled factory conditions.

17. Can PEB be used in residential buildings?

Yes, in hybrid systems.

18. What role do structural audits play?

They ensure long-term safety for both systems.

19. Which system is better for warehouses?

PEB.

20. Who should decide between PEB and conventional steel?

Qualified structural engineers.

Conclusion

In 2026, the debate between PEB and Conventional Steel Buildings is no longer about which system is “better”—but which system is more appropriate.

PEB offers speed, economy, and sustainability, while conventional steel provides flexibility and customization. The smartest projects are those where decisions are driven by engineering logic, site conditions, and long-term performance.

At Rakhra Associates – Structural Engineers in Chandigarh, the emphasis remains on educating stakeholders and promoting structurally sound decisions, ensuring that buildings are not just constructed—but engineered responsibly.