Blog

The Evolution of Multi-Storey Pre-Engineered Buildings in Urban Industrial Spaces

Urban India is facing a fundamental challenge: how to accommodate industrial growth within shrinking land parcels. As cities expand vertically and land prices rise, traditional single-storey industrial sheds are no longer viable in many urban and semi-urban zones.

This challenge has driven a major shift in structural engineering—the rise of multi-storey Pre-Engineered Buildings (PEB) in urban industrial environments.

At Rakhra Associates – Structural Engineers in Chandigarh, understanding how structural systems evolve is central to responsible engineering. This blog explores how multi-storey PEBs developed, why they are gaining acceptance, how they perform structurally, and what role they play in modern urban industrial planning.

Understanding Pre-Engineered Buildings (PEB)

A Pre-Engineered Building is a steel structure where components are:

- Designed using advanced structural software

- Fabricated in controlled factory environments

- Assembled at site using bolted connections

Originally, PEBs were limited to:

- Single-storey warehouses

- Storage sheds

- Large-span industrial halls

However, engineering advancements have pushed PEBs far beyond these limits.

Why Urban Industrial Spaces Needed a New Structural Approach

Key Urban Challenges

- Limited land availability

- High land acquisition costs

- Zoning restrictions

- Increased demand for vertical industrial facilities

- Faster project delivery requirements

Traditional RCC structures, while robust, often result in:

- Longer construction timelines

- Higher dead loads

- Reduced adaptability

Multi-storey PEBs emerged as a structural solution to urban constraints.

The Early Limitations of PEB in Multi-Storey Construction

Initially, PEB systems faced resistance due to:

- Concerns over lateral stability

- Limited understanding of seismic behavior

- Lack of hybrid design knowledge

- Dependence on conventional RCC for vertical loads

Early designs lacked:

- Adequate moment-resisting frames

- Advanced connection detailing

- Integrated seismic systems

Engineering Innovations That Enabled Multi-Storey PEBs

1. Advanced Structural Analysis Software

Modern software allows engineers to:

- Analyze dynamic loads

- Model seismic behavior

- Optimize member sizes for multi-level structures

2. Hybrid Structural Systems

Multi-storey PEBs often combine:

- RCC foundations and cores

- Steel superstructures

- Composite floors

This hybrid approach ensures:

- Stability

- Ductility

- Load efficiency

3. Improved Connection Design

Bolted moment connections and:

- Base plate optimization

- Braced frame systems

- Rigid joint detailing

have significantly improved multi-storey performance.

Structural Behavior of Multi-Storey PEBs

Load Distribution

- Vertical loads flow through steel columns to RCC foundations

- Lateral loads are resisted by bracing systems or RCC cores

Seismic Performance

When properly designed:

- Steel provides ductility

- Bracing dissipates energy

- Hybrid cores enhance stiffness

This combination is especially relevant in North Indian seismic zones, including Chandigarh and Punjab.

Advantages of Multi-Storey PEBs in Urban Industrial Use

1. Efficient Land Utilization

- More floor area on limited land

- Vertical expansion without footprint increase

2. Faster Construction Timelines

- Parallel fabrication and site preparation

- Reduced wet works

3. Reduced Structural Dead Load

- Lighter steel structures

- Smaller foundation requirements

4. Operational Flexibility

- Column-free interior layouts

- Easy future expansion or modification

Common Applications in Urban Industrial Zones

- Manufacturing units

- Logistics hubs

- Cold storage facilities

- Urban warehouses

- Data centers

- Multi-level industrial parks

Fire Safety Considerations

Multi-storey PEBs require:

- Fire-resistant coatings

- Fire compartmentalization

- Compliance with NBC norms

Fire engineering has become a design priority, not an afterthought.

Sustainability and Environmental Benefits

- Reduced material wastage

- Lower embodied carbon

- Recyclable steel components

- Faster construction reduces site emissions

Multi-storey PEBs align with India’s green building goals.

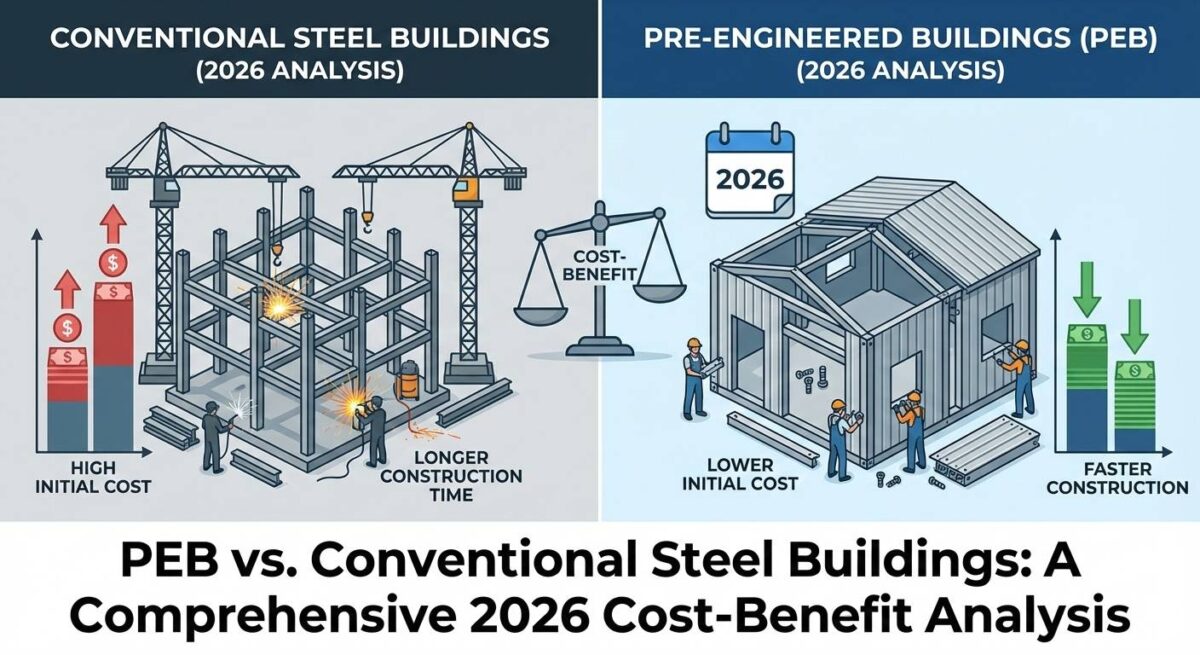

Cost Perspective: Long-Term vs Initial

While initial costs may be comparable to RCC:

- Faster completion improves ROI

- Lower foundation costs

- Reduced maintenance over lifecycle

Urban industrial developers increasingly consider time value of money, where PEBs offer a clear advantage.

Challenges and Engineering Responsibilities

Common Challenges

- Connection detailing

- Vibration control

- Fireproofing

- Coordination with MEP systems

These challenges reinforce the importance of experienced structural engineers.

Role of Structural Engineers in Multi-Storey PEBs

Structural engineers are responsible for:

- System selection

- Load path clarity

- Seismic detailing

- Code compliance

- Structural audits

At Rakhra Associates, the focus is always on engineering integrity and long-term performance.

Indian Codes Relevant to Multi-Storey PEB Design

- IS 800 – Steel structures

- IS 1893 – Earthquake resistance

- IS 875 – Load calculations

- IS 456 – RCC integration

- NBC 2016 – Fire and safety norms

Future of Multi-Storey PEBs in India

By 2030:

- Urban industrial parks will rely heavily on vertical steel structures

- Modular + PEB systems will merge

- Performance-based design will dominate

Multi-storey PEBs are no longer experimental—they are a structural necessity.

FAQs: Multi-Storey Pre-Engineered Buildings

1. What is a multi-storey PEB?

A steel building designed for multiple levels using PEB principles.

2. Are PEBs suitable for urban industrial areas?

Yes, especially where land is limited.

3. How many floors can a PEB have?

Multiple floors, depending on design and load requirements.

4. Are multi-storey PEBs earthquake resistant?

Yes, when designed as per IS 1893.

5. Do PEBs require RCC?

Often for foundations and cores.

6. Is fire safety a concern?

Fire safety must be addressed through design and protection systems.

7. Are PEBs faster to construct than RCC?

Yes, significantly.

8. Can PEBs support heavy industrial loads?

Yes, with proper design.

9. Are PEBs cost-effective long term?

Yes, due to reduced construction time and maintenance.

10. Do PEBs allow future expansion?

Yes, vertical and horizontal expansion is easier.

11. What role does bracing play?

Bracing provides lateral stability.

12. Are composite floors used in PEBs?

Yes, very commonly.

13. Is vibration control important?

Yes, especially for machinery floors.

14. Can PEBs be used for data centers?

Yes, they are well suited.

15. Are multi-storey PEBs common in India?

They are increasingly adopted.

16. Do PEBs comply with Indian codes?

Yes, when properly designed.

17. Is structural audit important for PEB buildings?

Absolutely.

18. Can old industrial buildings be converted to PEBs?

In some cases, yes.

19. Are PEBs environmentally sustainable?

Yes, due to steel recyclability.

20. Who should design multi-storey PEBs?

Qualified structural engineers with steel expertise.

Conclusion

The evolution of multi-storey Pre-Engineered Buildings marks a significant shift in how urban industrial spaces are planned and constructed. By combining engineering efficiency, speed, sustainability, and adaptability, PEB systems have transformed from simple sheds into complex vertical industrial structures.

At Rakhra Associates – Structural Engineers in Chandigarh, understanding and sharing such structural advancements is part of our commitment to safe, informed, and future-ready construction practices.