Blog

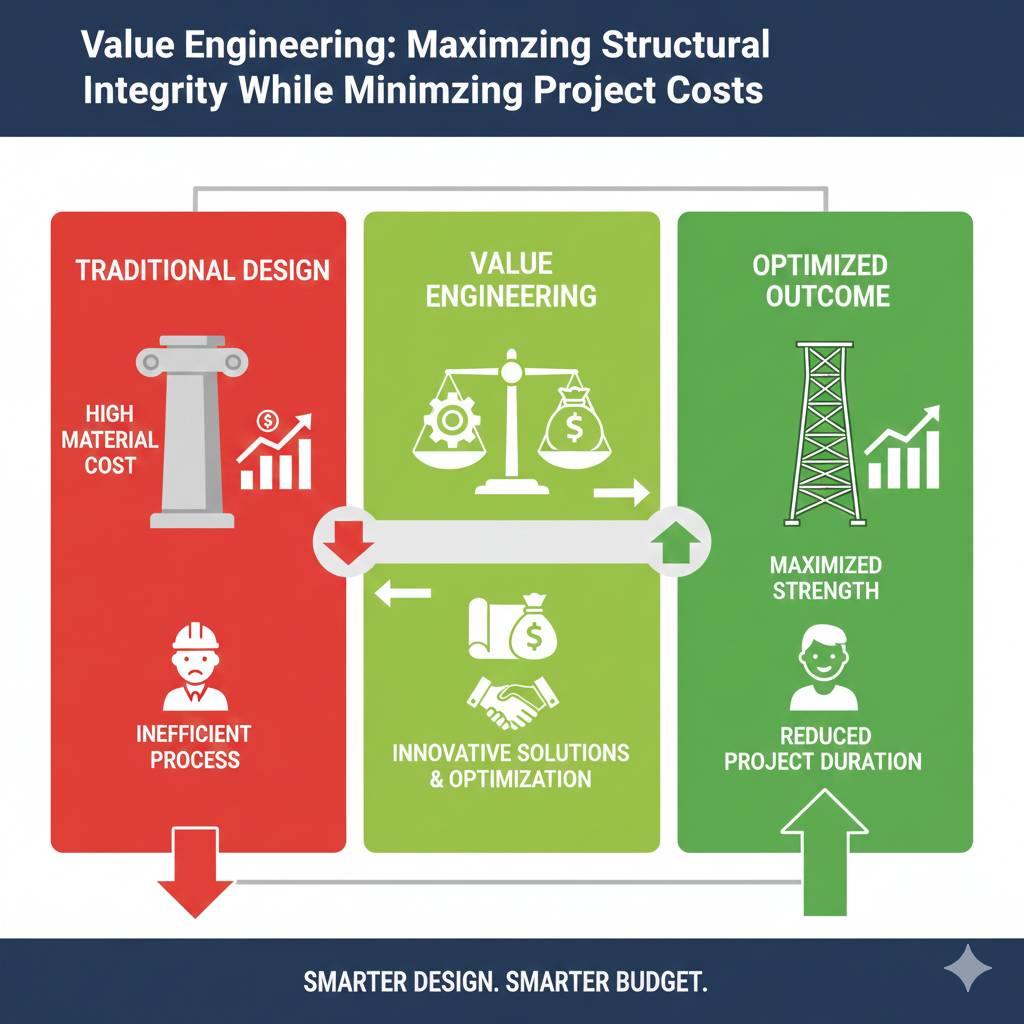

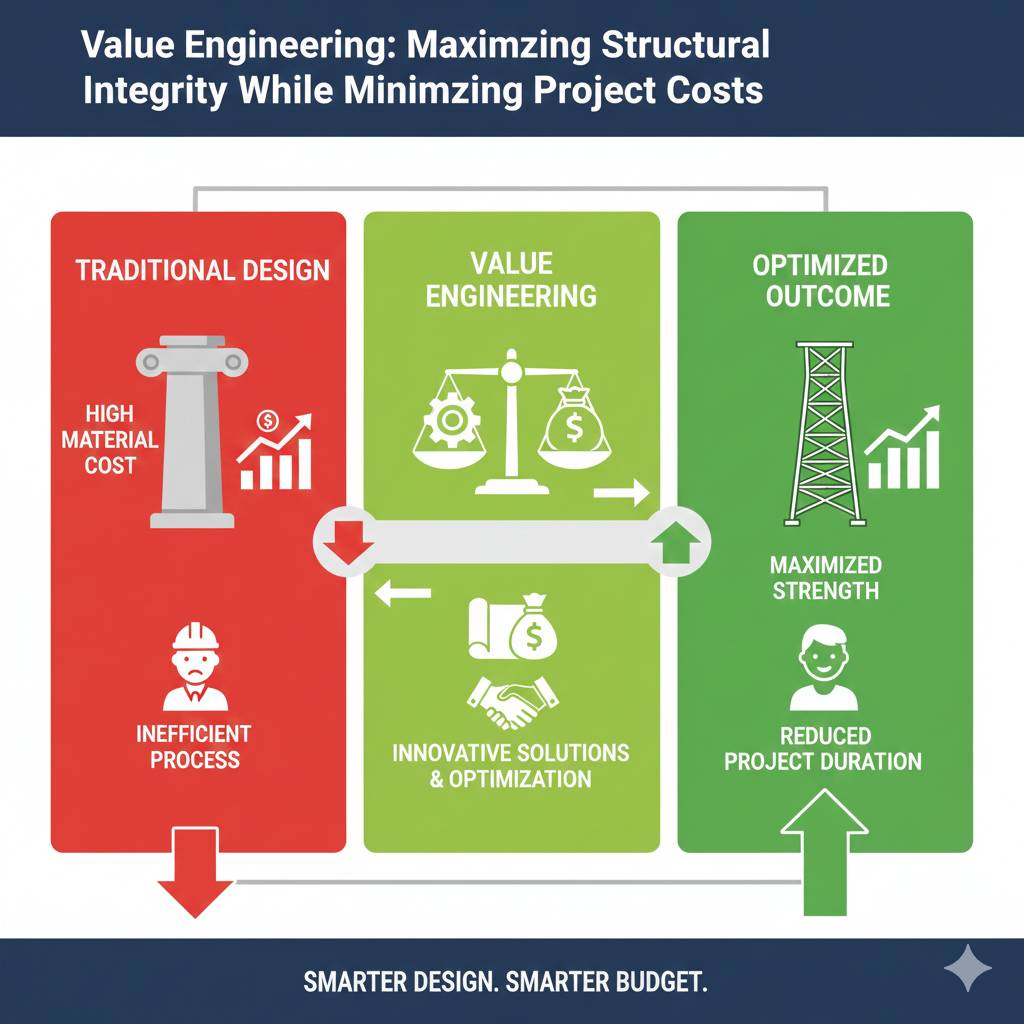

Maximizing Structural Integrity While Minimizing Project Costs

In modern construction, one of the biggest misconceptions is that lower cost means lower quality. From a structural engineering perspective, this belief is not only incorrect—it is inefficient.

The real challenge in today’s construction environment is not cutting costs blindly, but optimizing them intelligently. This is where Value Engineering (VE) plays a critical role.

At Rakhra Associates – Structural Engineers in Chandigarh, value engineering is viewed as a technical discipline, not a cost-cutting shortcut. This blog explains what value engineering truly means, how it improves structural integrity, and why it is essential for sustainable and economically viable construction projects.

What Is Value Engineering in Structural Design?

Value Engineering is a systematic approach that aims to:

- Improve functional performance

- Optimize material usage

- Reduce unnecessary costs

- Maintain or enhance safety and durability

In structural engineering, value engineering focuses on:

- Load efficiency

- Material optimization

- Design rationalization

- Lifecycle cost reduction

It is not about reducing safety margins, but about eliminating inefficiencies.

Core Principle of Value Engineering

The fundamental equation of value engineering is:

Value = Function ÷ Cost

Improving value can be achieved by:

- Enhancing function without increasing cost

- Maintaining function while reducing cost

- Improving function and reducing cost simultaneously

Why Value Engineering Is Essential in Today’s Construction Industry

Rising Challenges in Construction

- Escalating material prices

- Skilled labor shortages

- Tight project timelines

- Increasing regulatory compliance

- Sustainability requirements

Value engineering addresses these challenges by making structures economically efficient without compromising performance.

Value Engineering vs Cost Cutting

| Aspect | Cost Cutting | Value Engineering |

| Focus | Reduce expense | Improve efficiency |

| Safety | Often compromised | Never compromised |

| Approach | Reactive | Analytical |

| Outcome | Short-term savings | Long-term value |

Value engineering is a design philosophy, not a budget reaction.

Role of Structural Engineers in Value Engineering

Structural engineers are central to value engineering because:

- They understand load behavior

- They control material selection

- They define structural systems

- They ensure code compliance

At Rakhra Associates, value engineering begins at the conceptual design stage, not after drawings are finalized.

Key Areas Where Value Engineering Applies

1. Structural System Selection

Choosing the right system:

- RCC vs Steel vs Hybrid

- PEB vs Conventional steel

- Framed vs shear wall systems

Correct system selection alone can reduce costs by 10–25%.

2. Material Optimization

- Optimizing concrete grades

- Reducing over-reinforcement

- Using high-strength steel strategically

- Eliminating unnecessary safety margins

Material optimization improves both cost and sustainability.

3. Load Rationalization

Overestimation of loads leads to:

- Heavier sections

- Higher foundation costs

- Increased material usage

Value engineering ensures realistic and code-compliant load assumptions.

4. Member Size Optimization

Using:

- Tapered sections

- Variable beam depths

- Optimized column spacing

Results in:

- Reduced steel tonnage

- Efficient force transfer

5. Foundation Design Optimization

- Matching foundation type to soil conditions

- Avoiding blanket foundation designs

- Using geotechnical data effectively

Foundations often account for 20–30% of project cost, making them a major value engineering opportunity.

Value Engineering Across Project Stages

Concept Stage

- System selection

- Grid planning

- Preliminary load assessment

Design Development Stage

- Section optimization

- Reinforcement detailing

- Structural modeling

Construction Stage

- Constructability improvements

- Reduced wastage

- Faster execution

Structural Integrity and Value Engineering

A well-executed value engineering process:

- Improves load flow clarity

- Reduces stress concentrations

- Enhances seismic performance

- Minimizes long-term maintenance

Structural integrity is strengthened, not compromised.

Value Engineering and Seismic Safety

In seismic zones:

- Reducing dead load improves seismic response

- Proper ductility detailing saves material and lives

- Efficient lateral load systems reduce cost

Value engineering directly contributes to earthquake resilience.

Lifecycle Cost Perspective

True project cost is not just construction cost.

Lifecycle cost includes:

- Maintenance

- Repairs

- Retrofits

- Operational downtime

Value engineering focuses on long-term economic performance, not just initial savings.

Sustainability Through Value Engineering

- Reduced material usage

- Lower embodied carbon

- Efficient resource utilization

- Minimal wastage

Value engineering supports green construction goals naturally.

Common Misunderstandings About Value Engineering

- ❌ It compromises safety

- ❌ It is done after design approval

- ❌ It only applies to large projects

In reality, value engineering:

- Enhances safety

- Works best early

- Benefits projects of all sizes

Importance of Structural Audits in Value Engineering

Structural audits:

- Validate design assumptions

- Identify overdesign

- Ensure performance compliance

Audits help maintain value throughout a structure’s life.

Indian Codes Supporting Value Engineering

- IS 456 – Rational concrete design

- IS 800 – Steel optimization

- IS 1893 – Seismic efficiency

- IS 875 – Load rationalization

- NBC 2016 – Performance-based design

Codes allow flexibility—engineering judgment applies value.

FAQs: Value Engineering in Structural Design

1. What is value engineering in construction?

A method to optimize cost while maintaining performance and safety.

2. Is value engineering the same as cost cutting?

No, it focuses on efficiency, not compromise.

3. When should value engineering be done?

Ideally at the conceptual design stage.

4. Can value engineering improve safety?

Yes, by improving load paths and detailing.

5. Does value engineering reduce material quality?

No, it optimizes usage.

6. Who performs value engineering?

Structural engineers and design professionals.

7. Is value engineering suitable for small projects?

Yes, even more impactful in smaller budgets.

8. How does value engineering reduce foundation cost?

By matching design to soil behavior.

9. Can value engineering delay projects?

No, it often speeds them up.

10. Does value engineering affect approvals?

No, designs remain code-compliant.

11. Is value engineering useful in seismic zones?

Yes, it improves seismic efficiency.

12. Can value engineering reduce steel quantity?

Yes, significantly.

13. Does it apply to RCC structures?

Absolutely.

14. Is value engineering allowed under Indian codes?

Yes, codes encourage optimization.

15. Can value engineering reduce maintenance costs?

Yes, by improving durability.

16. Does value engineering affect aesthetics?

No, structural changes are usually invisible.

17. Can value engineering be done after construction starts?

Limited benefits compared to early stages.

18. Is value engineering sustainable?

Yes, it reduces resource consumption.

19. Does value engineering apply to retrofitting projects?

Yes, very effectively.

20. Is value engineering a one-time process?

No, it continues through the project lifecycle.

Conclusion

Value engineering is not about building cheaper—it is about building smarter. By focusing on function, efficiency, and long-term performance, value engineering ensures that structural integrity is preserved while unnecessary costs are eliminated.

At Rakhra Associates – Structural Engineers in Chandigarh, value engineering is approached as a responsibility toward safe, sustainable, and economically sound construction, contributing to better-built environments and informed decision-making across the industry.