Blog

Key Indicators Your Industrial Building Needs Retrofitting

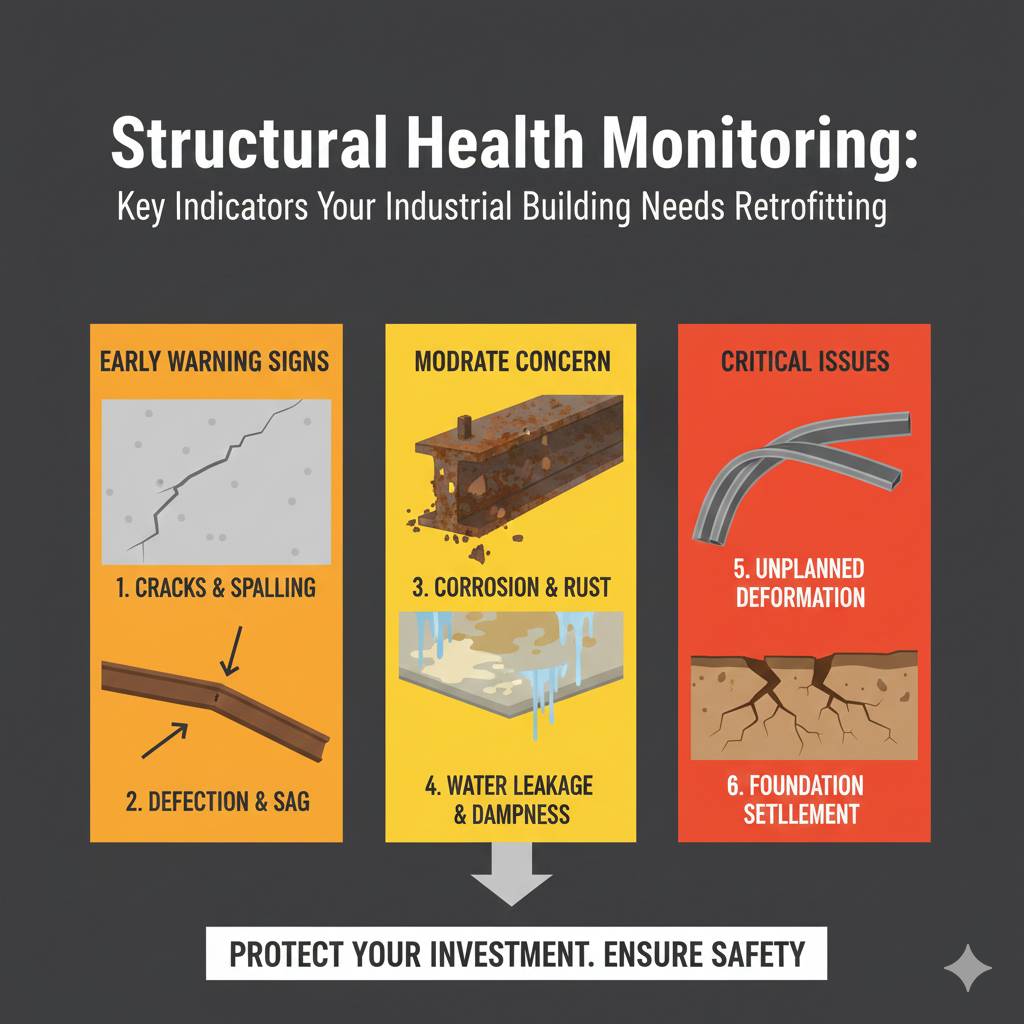

Industrial buildings are designed for long service life, but age, loading changes, environmental exposure, and material degradation gradually reduce structural performance. Structural Health Monitoring (SHM) helps identify early warning signs—long before visible failure occurs.

What Is Structural Health Monitoring (SHM)?

Structural Health Monitoring is the process of:

- Observing structural behavior over time

- Measuring performance under real loads

- Identifying distress before failure

It combines engineering assessment with data-driven evaluation.

Why SHM Is Critical for Industrial Buildings

Industrial structures face:

- Heavy dynamic loads

- Machinery vibrations

- Chemical and thermal exposure

Without monitoring, deterioration often remains unnoticed until it becomes critical.

Visible Cracking Beyond Design Expectations

Cracks that indicate concern include:

- Diagonal shear cracks

- Widening flexural cracks

- Repeated cracking at the same location

These often signal overstress or material fatigue.

Excessive Deflection or Sagging Members

Warning signs include:

- Sagging beams or slabs

- Uneven floors

- Misaligned roof elements

Excessive deflection suggests loss of stiffness or increased loading.

Corrosion of Reinforcement or Structural Steel

Corrosion indicators:

- Rust stains

- Concrete spalling

- Section loss in steel members

Corrosion reduces load-carrying capacity and accelerates failure.

Abnormal Vibrations in Floors or Frames

Vibration issues may result from:

- Machinery upgrades

- Structural weakening

- Resonance conditions

Persistent vibration affects both safety and equipment performance.

Change in Structural Usage or Load Patterns

Buildings originally designed for:

- Light manufacturing

- Storage

May later carry heavier equipment or stacked loads—often without structural upgrades.

Settlement and Foundation Distress

Key indicators include:

- Uneven floor levels

- Wall separation

- Cracks near columns or footings

Foundation movement directly impacts superstructure stability.

Water Seepage and Moisture Ingress

Moisture exposure leads to:

- Reinforcement corrosion

- Concrete strength reduction

- Loss of durability

Water-related damage is often slow but progressive.

Deterioration Due to Environmental Exposure

Industrial buildings may be exposed to:

- Chemicals

- High humidity

- Temperature cycling

These conditions accelerate material degradation beyond design assumptions.

Ageing Structures Beyond Design Life

Many industrial buildings operate:

- Beyond their original design life

- Without periodic structural evaluation

Ageing alone is a valid reason for SHM and retrofitting assessment.

Damage from Seismic or Wind Events

Even moderate events can cause:

- Microcracking

- Joint distress

- Connection weakening

Post-event monitoring is essential even when damage appears minor.

Instrument-Based Structural Monitoring

SHM tools may include:

- Crack gauges

- Strain sensors

- Vibration monitors

These help quantify structural behavior instead of relying only on visual inspection.

When Monitoring Indicates the Need for Retrofitting

Retrofitting becomes necessary when:

- Structural capacity reduces below demand

- Progressive deterioration is detected

- Safety margins are compromised

Early intervention minimizes cost and downtime.

Benefits of Early Retrofitting Decisions

Proactive retrofitting results in:

- Lower repair costs

- Improved safety

- Extended service life

Delayed action increases structural and financial risk.

Role of Structural Engineers in SHM

Structural engineers:

- Interpret monitoring data

- Assess residual strength

- Recommend appropriate strengthening methods

Engineering judgment is critical for correct decision-making.

Conclusion

Structural Health Monitoring provides objective insight into the real condition of industrial buildings. Recognizing early indicators—such as cracking, deflection, corrosion, and vibration—allows timely retrofitting and prevents unexpected failures.

For industrial facilities, SHM is not a reactive measure but a preventive engineering practice that safeguards safety, performance, and long-term asset value.