Blog

Sustainable Structural Engineering

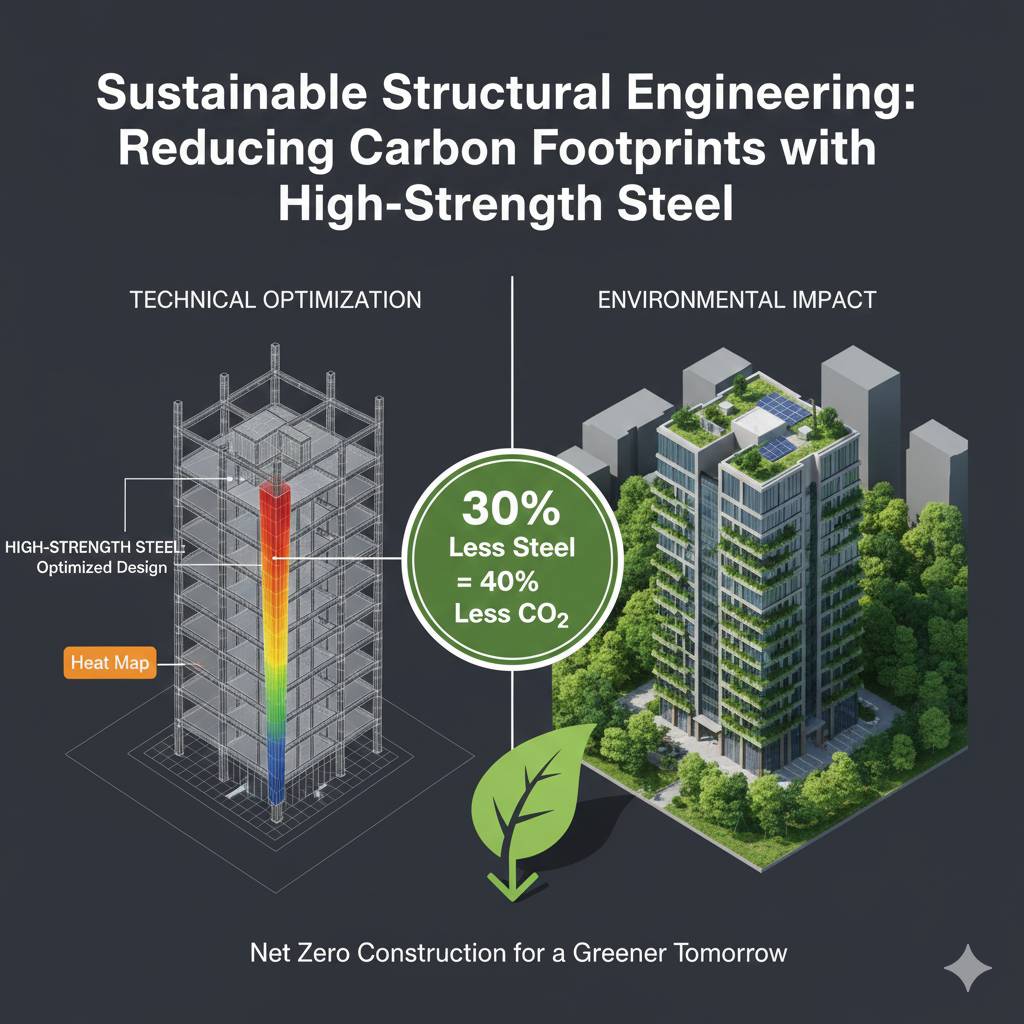

Sustainability is no longer limited to green finishes or energy-efficient equipment. In structural engineering, material selection and structural efficiency play a decisive role in reducing a building’s overall carbon footprint. Among all construction materials, steel—when used intelligently—has emerged as a powerful enabler of sustainable structural design.

High-strength steel allows engineers to achieve greater load-carrying capacity with less material, directly reducing embodied carbon while maintaining safety and durability.

Understanding Sustainability in Structural Engineering

Structural sustainability focuses on:

- Efficient material usage

- Longer service life

- Reduced environmental impact

- Lower maintenance and demolition waste

The goal is to achieve maximum structural performance with minimum resource consumption.

What Is High-Strength Steel?

High-strength steel refers to steel grades with:

- Higher yield strength

- Improved tensile capacity

- Enhanced fatigue resistance

These steels outperform conventional grades while requiring smaller cross-sections.

Carbon Footprint of Conventional Structural Steel

Traditional steel construction contributes to carbon emissions due to:

- High material volume

- Energy-intensive manufacturing

- Transportation weight

- Overdesign practices

Reducing steel quantity directly lowers embodied carbon.

How High-Strength Steel Reduces Carbon Emissions

High-strength steel enables:

- Thinner sections

- Reduced member sizes

- Fewer columns and beams

- Lower total tonnage

Less steel production means lower CO₂ emissions at the source.

Material Efficiency and Structural Optimization

Structural optimization using high-strength steel results in:

- Efficient load paths

- Reduced redundancy

- Leaner framing systems

Engineering precision replaces excessive material usage.

Impact on Foundation Design

Lighter superstructures lead to:

- Smaller foundations

- Reduced concrete volume

- Lower excavation requirements

This creates a compound sustainability benefit across the project.

Transportation and Logistics Benefits

High-strength steel reduces:

- Truckloads to site

- Fuel consumption

- Handling time

Logistics-related emissions are often overlooked but significant.

Construction Speed and Sustainability

Using fewer and lighter components:

- Speeds up erection

- Reduces on-site energy usage

- Minimizes equipment runtime

Faster construction equals lower environmental impact.

Lifecycle Carbon Reduction

High-strength steel offers:

- Longer service life

- Better fatigue resistance

- Lower maintenance frequency

Sustainability improves when structures last longer without intervention.

Recyclability of High-Strength Steel

Steel is:

- 100% recyclable

- Reusable without quality loss

- Part of a circular economy

High-strength grades retain full recyclability benefits.

Reduced Demolition Waste

Lean structural systems:

- Generate less demolition debris

- Lower landfill pressure

- Support sustainable urban redevelopment

End-of-life impact matters in sustainable engineering.

Performance in High-Rise and Industrial Structures

High-strength steel is especially effective for:

- Industrial sheds

- High-rise frames

- Long-span structures

These building types benefit most from material efficiency.

High-Strength Steel in Seismic Design

Sustainability also means resilience:

- Higher ductility

- Better energy dissipation

- Reduced repair after earthquakes

Resilient structures reduce post-disaster reconstruction emissions.

Compatibility with PEB and Hybrid Systems

High-strength steel integrates seamlessly with:

- Pre-Engineered Buildings

- Hybrid RCC–steel systems

- Modular construction

These systems maximize sustainability benefits.

Role of Structural Engineers in Sustainable Steel Usage

Engineers contribute by:

- Selecting appropriate grades

- Avoiding overdesign

- Optimizing member sizing

- Ensuring code compliance

Sustainability starts at the design desk.

Indian Standards Supporting High-Strength Steel

Relevant codes include:

- IS 800 (Steel design)

- IS 2062 (Steel grades)

- IS 875 (Loading)

Modern codes support efficient steel usage when applied correctly.

Cost vs Carbon: A Balanced Perspective

High-strength steel may cost more per ton, but:

- Requires fewer tons

- Reduces foundation costs

- Saves construction time

Sustainability and economy often align.

Digital Design Tools Enhancing Sustainable Outcomes

Advanced analysis tools allow:

- Accurate force modeling

- Section optimization

- Reduced material waste

Technology amplifies sustainable engineering decisions.

Challenges in Adopting High-Strength Steel

Common challenges include:

- Lack of awareness

- Improper fabrication practices

- Inadequate detailing

Education and expertise resolve most barriers.

Future of Sustainable Structural Engineering

Trends shaping the future:

- Performance-based design

- Low-carbon steel production

- AI-driven optimization

- Lifecycle-based structural decisions

Sustainability will become a baseline, not a feature.

Conclusion

High-strength steel plays a crucial role in reducing carbon footprints without compromising safety, durability, or performance. By enabling material efficiency, lighter structures, faster construction, and longer service life, it aligns perfectly with the goals of sustainable structural engineering. When applied thoughtfully, it transforms steel from a high-carbon material into a solution for responsible construction.