Blog

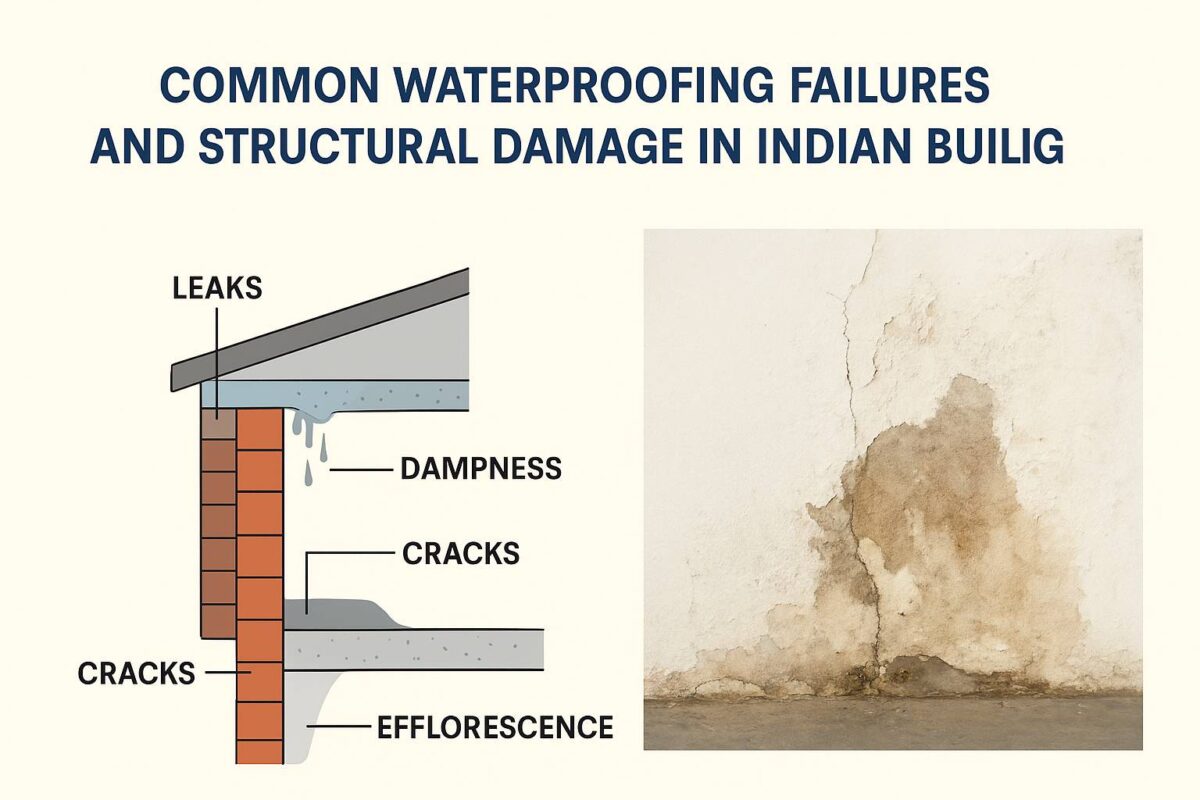

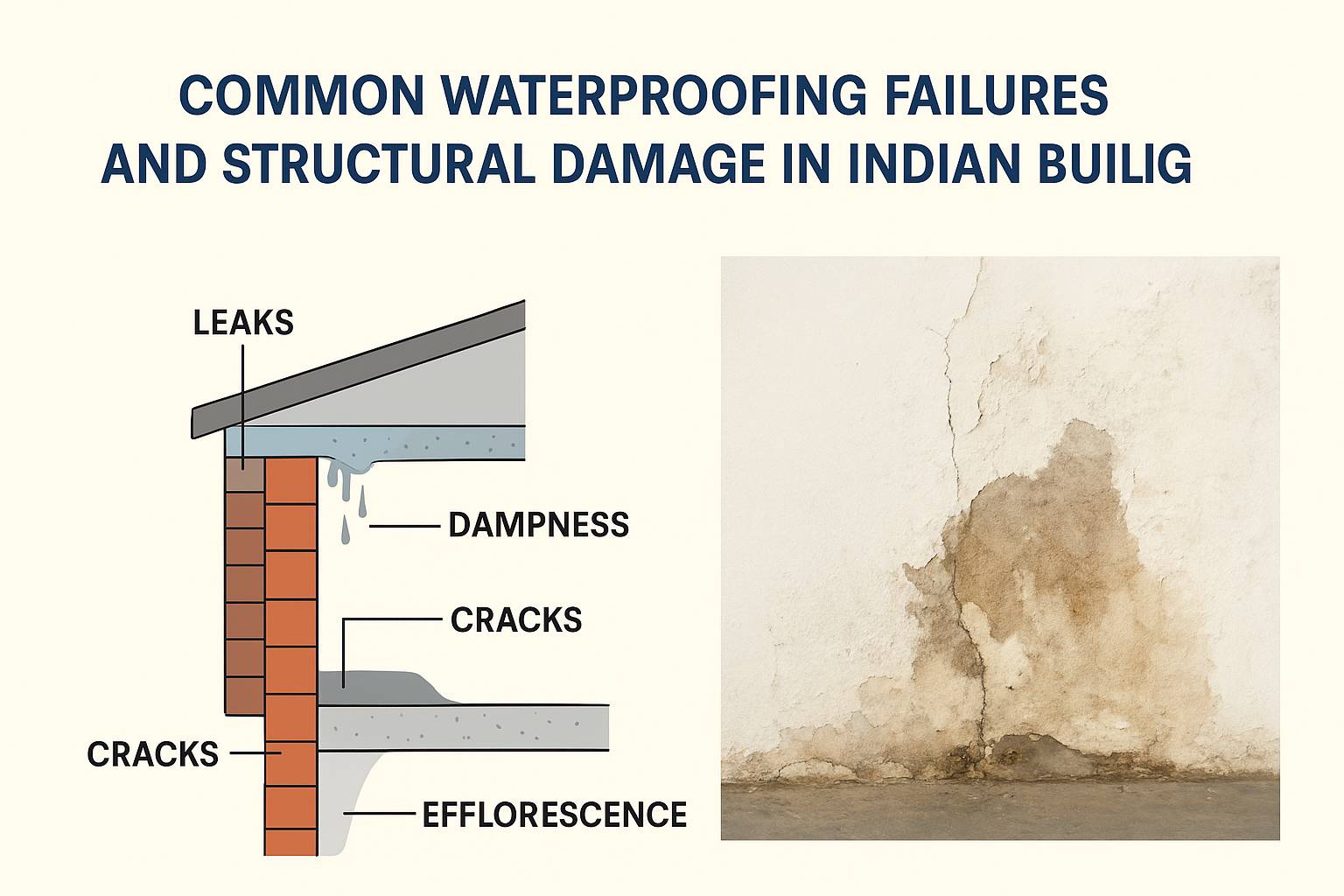

Common Waterproofing Failures and Structural Damage in Indian Buildings

Introduction: The Hidden Enemy Beneath the Surface

In India’s varied climate—from humid coastal regions to the monsoon-heavy north—waterproofing is one of the most critical yet overlooked aspects of building design. Leaks, dampness, and seepage not only ruin aesthetics but also weaken the structure from within, reducing its lifespan drastically.

At Rakhra Associates, a trusted name in structural engineering in Chandigarh, we’ve seen how inadequate waterproofing leads to severe structural damage, costly repairs, and even building failures over time. Understanding the root causes and prevention methods is essential for architects, builders, and homeowners alike.

Understanding Waterproofing in Indian Context

Waterproofing is a process that prevents water ingress into structural elements like:

- Roofs and terraces

- Basements

- Bathrooms and wet areas

- Water tanks and swimming pools

- Exterior walls and balconies

Given India’s high rainfall intensity and temperature variations, the expansion and contraction of building materials accelerate the deterioration of waterproofing membranes.

Top 10 Common Waterproofing Failures in Indian Buildings

1. Poor Surface Preparation

One of the most frequent causes of waterproofing failure is applying membranes or coatings on dirty, wet, or uneven surfaces.

Effect: Lack of adhesion causes peeling and cracks, allowing water infiltration.

Solution: Surfaces must be clean, dry, and primed before application, ensuring better bonding.

2. Incorrect Material Selection

Choosing the wrong waterproofing product for a specific area (like using acrylic for basements) leads to premature failure.

Effect: Coatings lose elasticity and crack under pressure or moisture.

Solution: Use polyurethane or crystalline-based waterproofing for below-ground structures and UV-resistant membranes for exposed areas.

3. Improper Application Techniques

Even the best materials fail if applied incorrectly.

Effect: Inconsistent thickness, poor overlaps, and air bubbles lead to early leaks.

Solution: Ensure trained professionals apply materials as per manufacturer’s specifications and curing time guidelines.

4. Lack of Expansion Joints

Many Indian buildings ignore expansion and contraction joints.

Effect: Thermal movements cause cracks in waterproofed surfaces, allowing seepage.

Solution: Incorporate elastomeric sealants and flexible membranes at joints to absorb structural movement.

5. Drainage System Failures

Blocked or poorly designed drainage outlets cause water accumulation on roofs and balconies.

Effect: Ponding water degrades the waterproof layer over time.

Solution: Provide adequate slope and multiple drain points, with regular cleaning and maintenance.

6. Cracks in Structural Elements

Cracks due to settlement, shrinkage, or seismic activity create water pathways.

Effect: Seepage enters the RCC matrix, corroding steel reinforcements.

Solution: Repair structural cracks using epoxy or polyurethane grouting before reapplying waterproofing layers.

7. Poor Detailing Around Critical Areas

Junctions between walls and floors, parapets, or pipe penetrations are common leakage zones.

Effect: Capillary action allows water entry through tiny gaps.

Solution: Use fillet coves and reinforcement fabric at joints to ensure watertight transitions.

8. Aging and Weathering of Waterproof Layers

Over time, UV rays, pollution, and temperature changes degrade membranes.

Effect: Loss of elasticity and cracks appear, allowing water ingress.

Solution: Perform regular inspections and apply protective coatings or overlays every 5–7 years.

9. Basement Waterproofing Failures

Basements in Indian cities like Chandigarh, Mohali, and Delhi often face hydrostatic pressure due to high water tables.

Effect: Water seeps through retaining walls and floor slabs, damaging interiors and electrical systems.

Solution: Use pressure-injected crystalline waterproofing systems with external drainage membranes for lasting protection.

10. Lack of Maintenance

Even a perfect waterproofing system can fail without maintenance.

Effect: Blocked outlets, damaged membranes, and debris buildup cause localized failures.

Solution: Regular visual inspections and preventive maintenance extend waterproofing life by decades.

Impact of Waterproofing Failures on Structural Integrity

1. Corrosion of Reinforcement

Water entering the concrete leads to rust formation, which expands and cracks the concrete cover—weakening beams, slabs, and columns.

2. Reduced Load-Bearing Capacity

Continuous seepage leads to loss of concrete strength and spalling, directly affecting safety.

3. Mold and Health Hazards

Damp walls promote mold growth, causing respiratory issues and unpleasant odors indoors.

4. Aesthetic Degradation

Peeling paint, efflorescence, and stains on walls reduce the building’s appearance and resale value.

Case Study: Terrace Waterproofing Failure in Chandigarh

A commercial building in Sector 34, Chandigarh, suffered persistent leaks despite multiple repairs. Upon inspection by Rakhra Associates, it was found that:

- Inadequate slope caused ponding water.

- Non-UV-resistant bituminous membranes had deteriorated.

- Expansion joints were missing.

Solution Implemented:

- Re-screeding with proper slope

- Installation of PU liquid membrane

- Use of elastomeric joint sealants

Result: 100% waterproofed terrace and no leakage even after two monsoon cycles.

Best Practices for Long-Term Waterproofing

| Area | Recommended System | Expected Lifespan |

| Roofs/Terraces | Polyurethane or APP membrane | 10–15 years |

| Basements | Crystalline waterproofing + drainage layer | 20+ years |

| Bathrooms | Cementitious coating + tile grout sealant | 10 years |

| Exterior Walls | Elastomeric paint or acrylic coatings | 8–10 years |

| Water Tanks | Food-grade epoxy or crystalline coating | 15+ years |

These systems, when implemented under professional supervision, prevent structural deterioration and long-term repair costs.

Role of Structural Engineers in Waterproofing Design

At Rakhra Associates, structural engineers integrate waterproofing into the design phase, not as an afterthought.

They ensure:

- Proper drainage slopes in structural drawings

- Water-retaining structures designed per IS 3370

- Selection of materials compatible with structural load requirements

This engineering-led approach guarantees performance and durability.

Future Trends in Waterproofing Technology

- Nano-based coatings for superior adhesion

- Self-healing concrete using crystalline growth

- Smart membranes with embedded leak sensors

- Eco-friendly materials that reduce VOC emissions

These innovations promise longer lifespans and lower maintenance, ideal for smart cities and sustainable housing.

FAQs on Waterproofing and Structural Damage

Q1. Why is waterproofing essential in RCC structures?

Because RCC is porous, allowing water ingress that corrodes steel reinforcement and reduces strength.

Q2. How often should waterproofing be inspected?

At least once every 2–3 years, or immediately after visible signs like dampness or cracks.

Q3. Can waterproofing be done on old buildings?

Yes, through surface repair, injection grouting, and membrane overlays.

Q4. What’s the best waterproofing method for terraces in India?

Polyurethane liquid membrane or APP membrane with UV resistance is ideal.

Q5. How much does waterproofing cost in India?

Typically ranges from ₹50 to ₹300 per sq. ft., depending on material and area.

Q6. How does Rakhra Associates ensure waterproofing success?

By integrating structural design, material testing, and site supervision to ensure system durability.

Conclusion: Prevention is Always Cheaper than Repair

Waterproofing is not a luxury—it’s a structural necessity. Most failures in Indian buildings arise from poor detailing, material selection, or negligence in maintenance. By addressing these early, building owners can save 30–40% in long-term repair costs and extend their structure’s life by decades.

With Rakhra Associates – Structural Engineers in Chandigarh, you get comprehensive design-to-execution waterproofing solutions, ensuring your building stays safe, dry, and durable through every monsoon.