Blog

How Early Structural Consultation with Rakhra Associates Optimizes Your Construction Budget

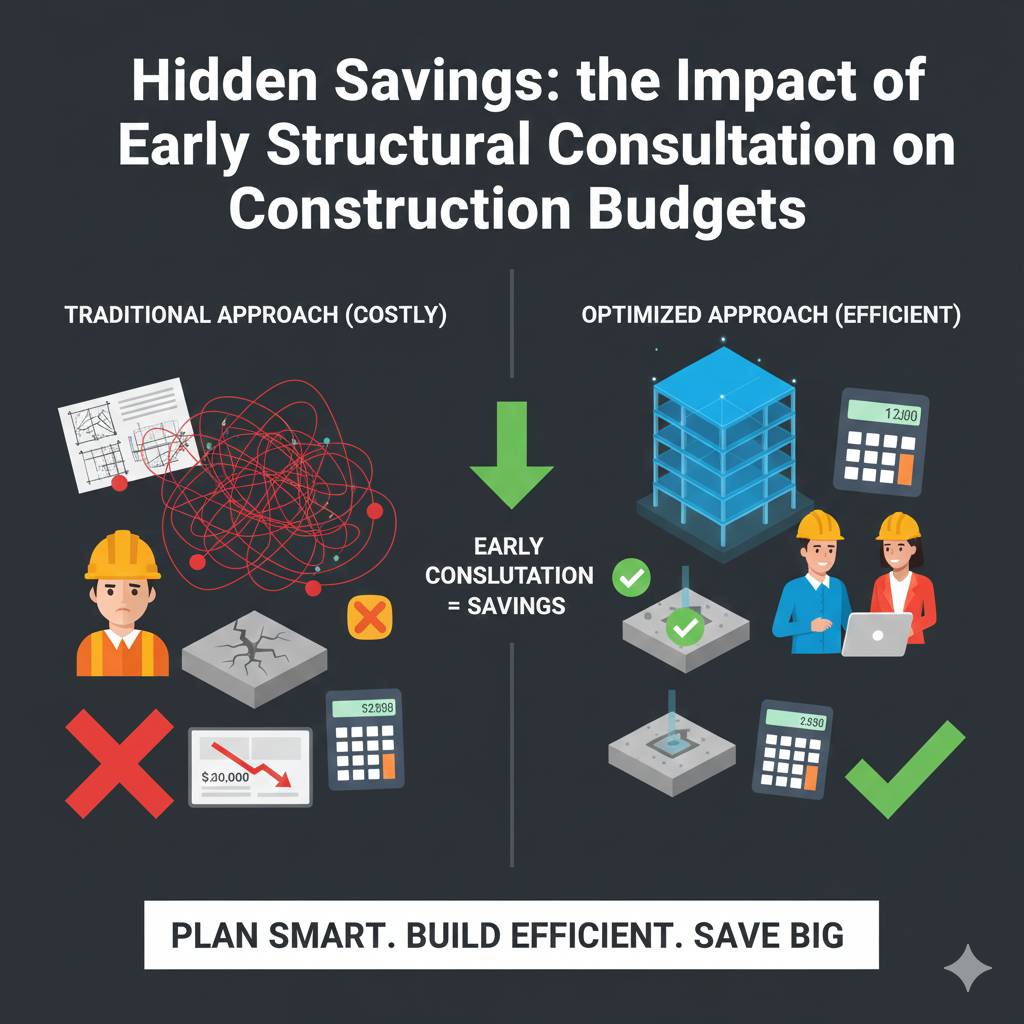

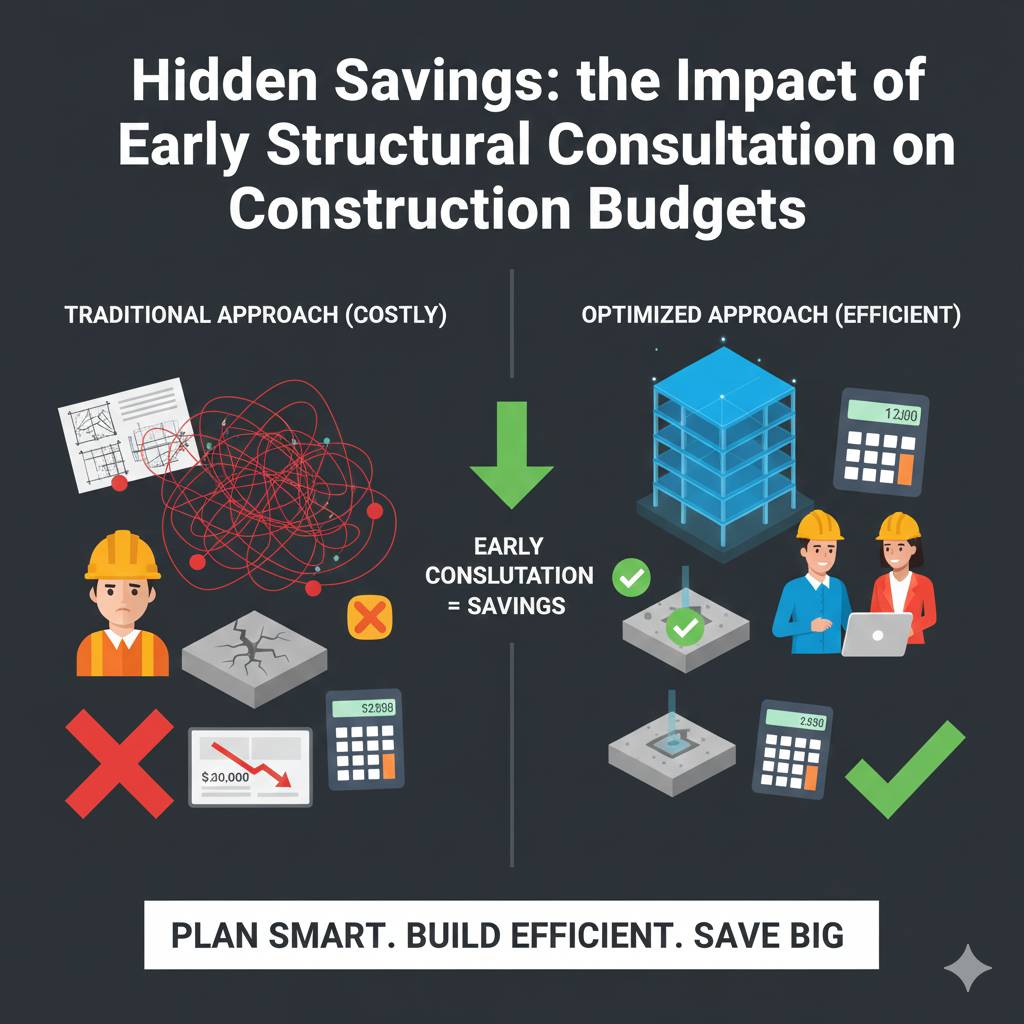

Building a new commercial, industrial, or residential project in Chandigarh or anywhere else is a massive undertaking. Many project owners instinctively focus on architectural aesthetics and immediate material procurement costs. Often, a structural engineer is only brought into the picture once preliminary designs are well-advanced. This common oversight, however, can lead to significant missed opportunities for cost savings and can even introduce budget-busting delays and costly reworks later on.

At Rakhra Associates, a leading structural engineering consultancy in Chandigarh, we firmly believe that engaging a structural engineer early in your project's lifecycle isn't just a best practice – it’s a strategic move to unlock "hidden savings" that dramatically optimize your overall construction budget.

Why Early Engagement with Rakhra Associates is a Game-Changer

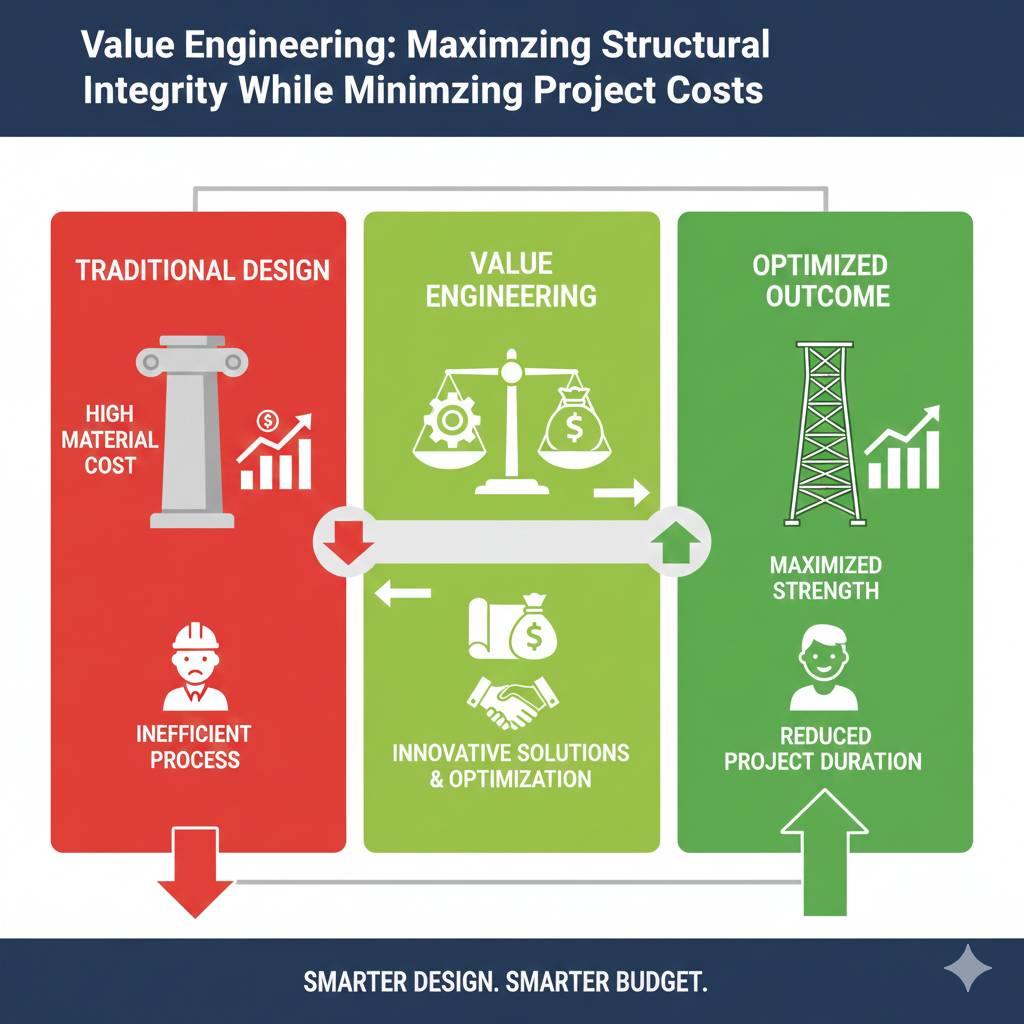

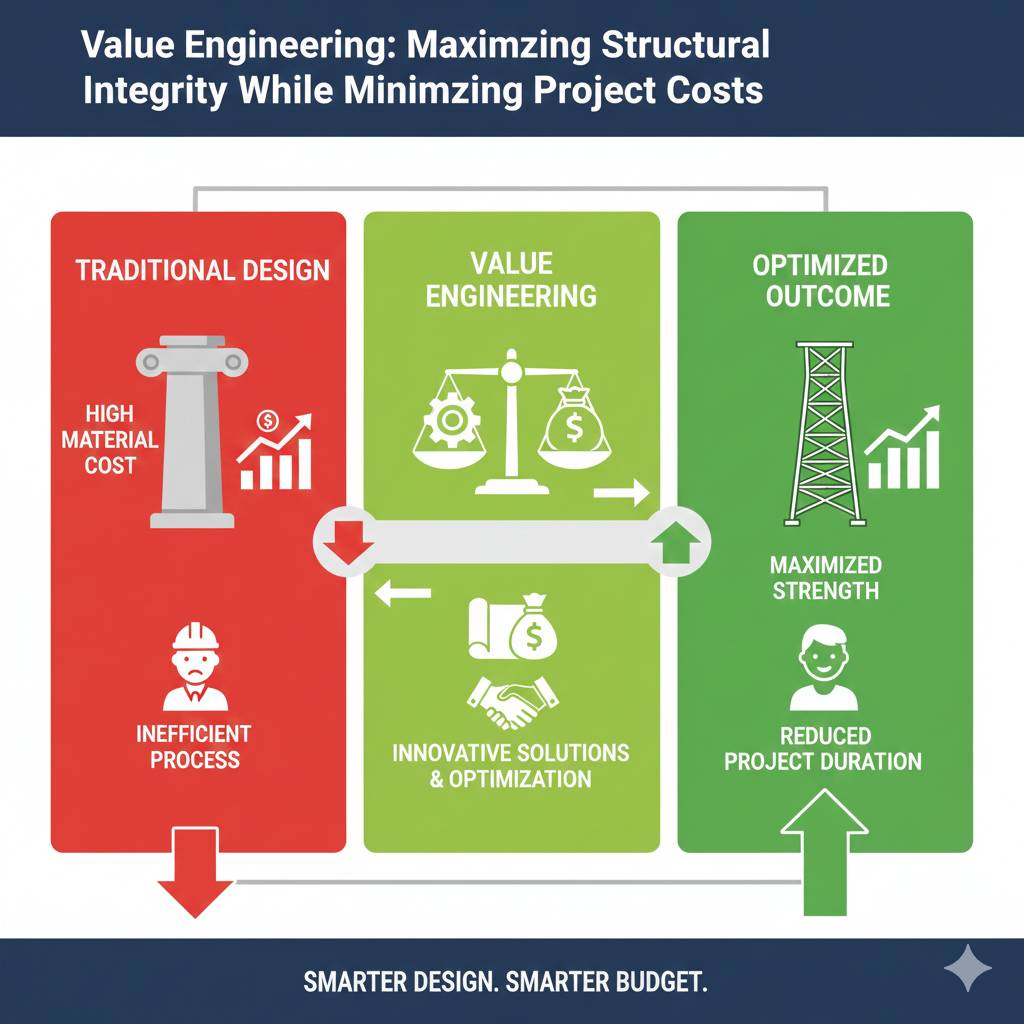

Think of your building's structural system as its very backbone. It dictates everything from material usage and construction timelines to long-term durability and even the eventual aesthetic possibilities. When the expert team at Rakhra Associates is involved right from the conceptual or schematic design phase, we can collaborate proactively with your architects, developers, and contractors. This integrated approach ensures that critical foundational decisions are made with structural efficiency and cost-effectiveness at their core, rather than forcing structural elements into an already rigid design.

Here’s how early structural consultation with Rakhra Associates translates into tangible savings for your project:

1. Smart Material Optimization and Waste Reduction

One of the most direct ways early structural input saves money is through intelligent material selection and precise optimization. Our experienced structural engineers at Rakhra Associates can:

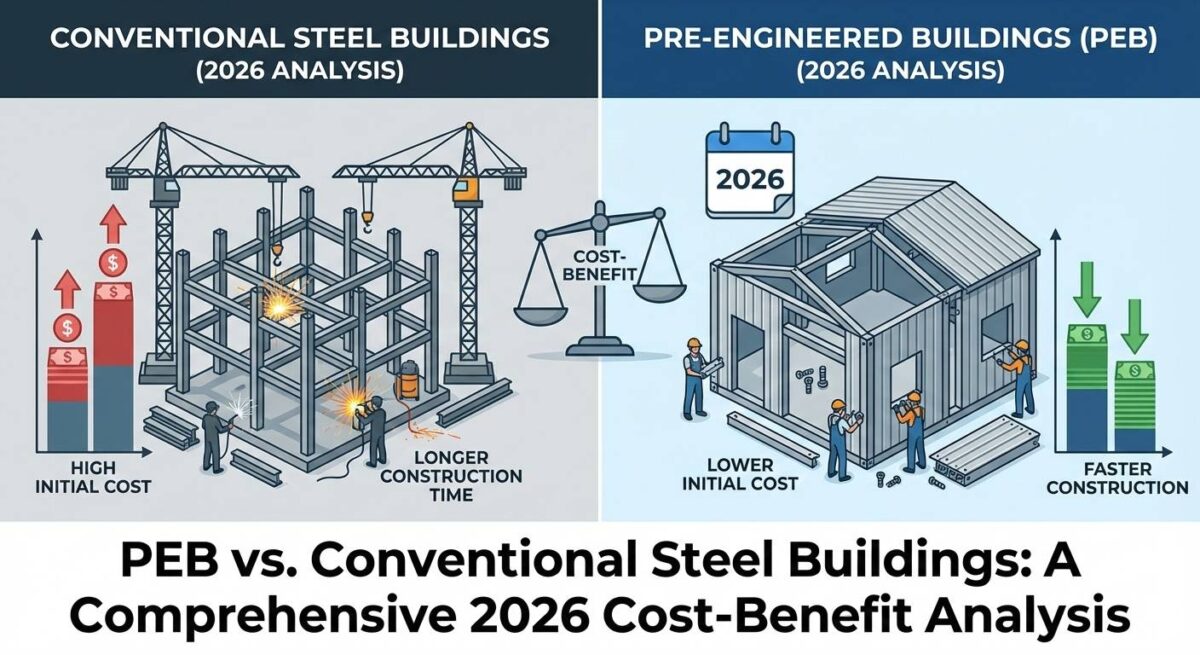

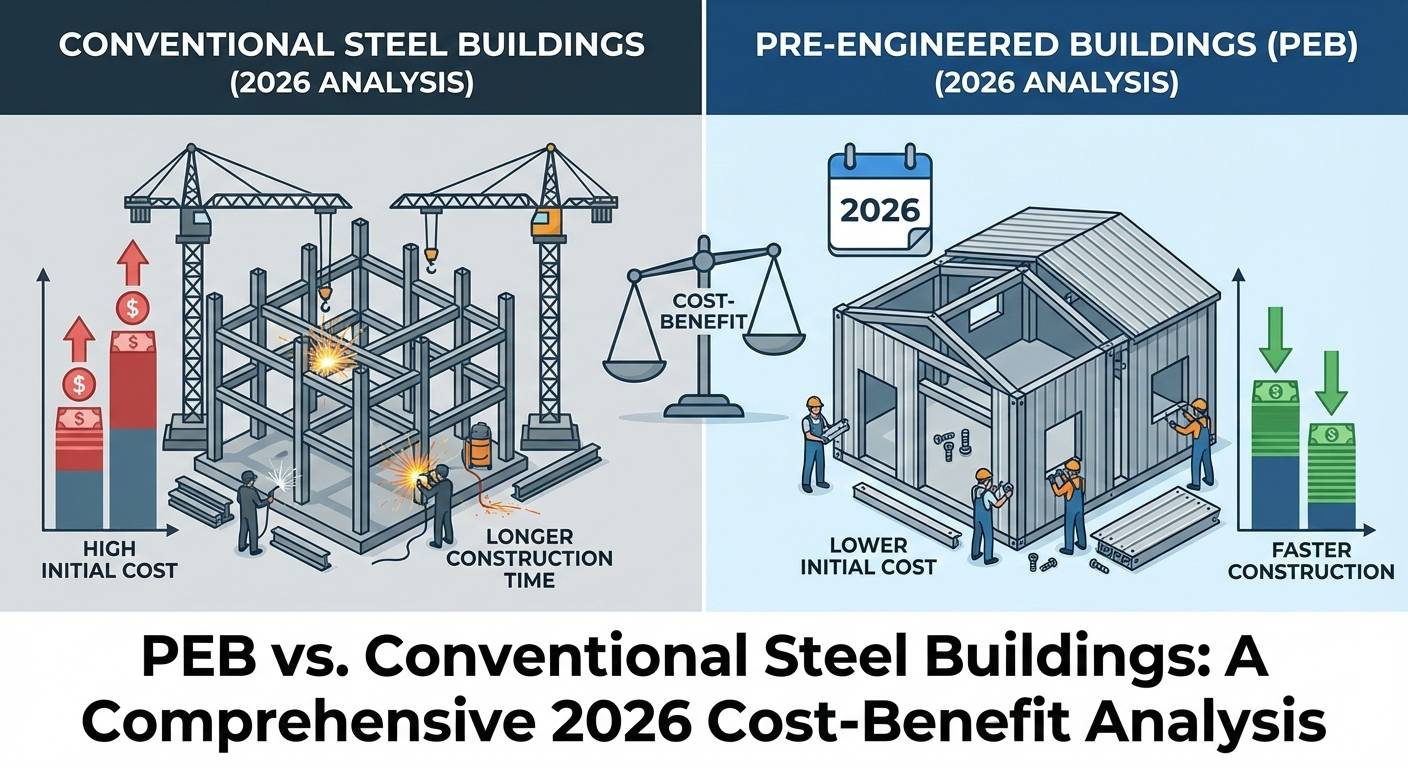

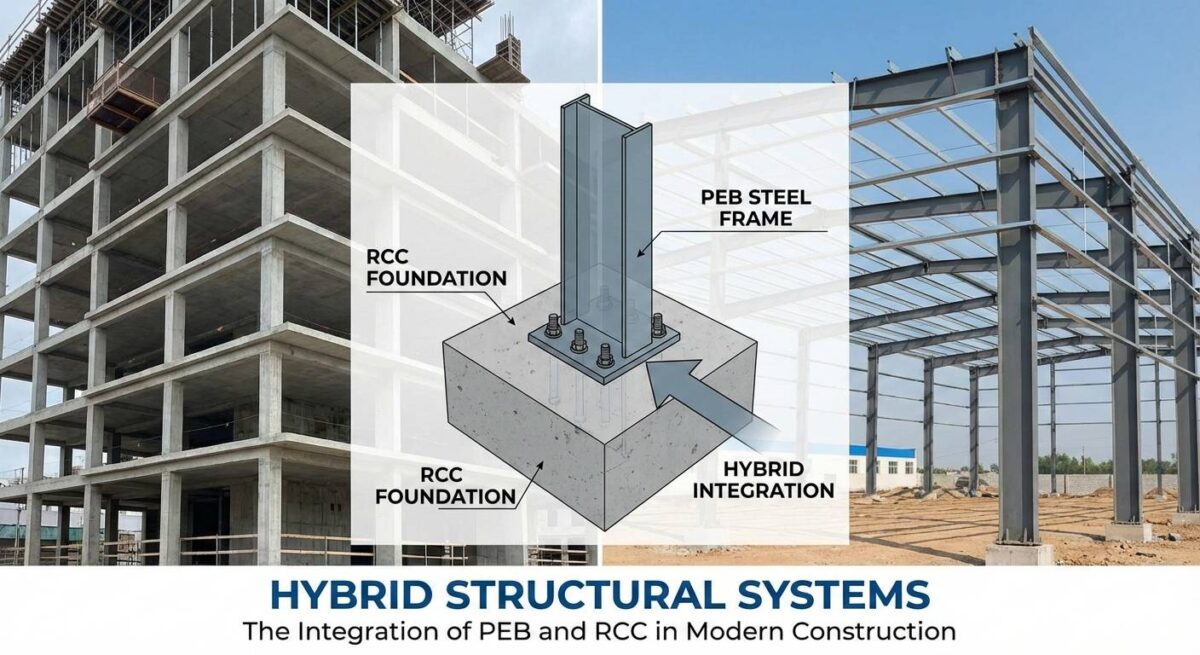

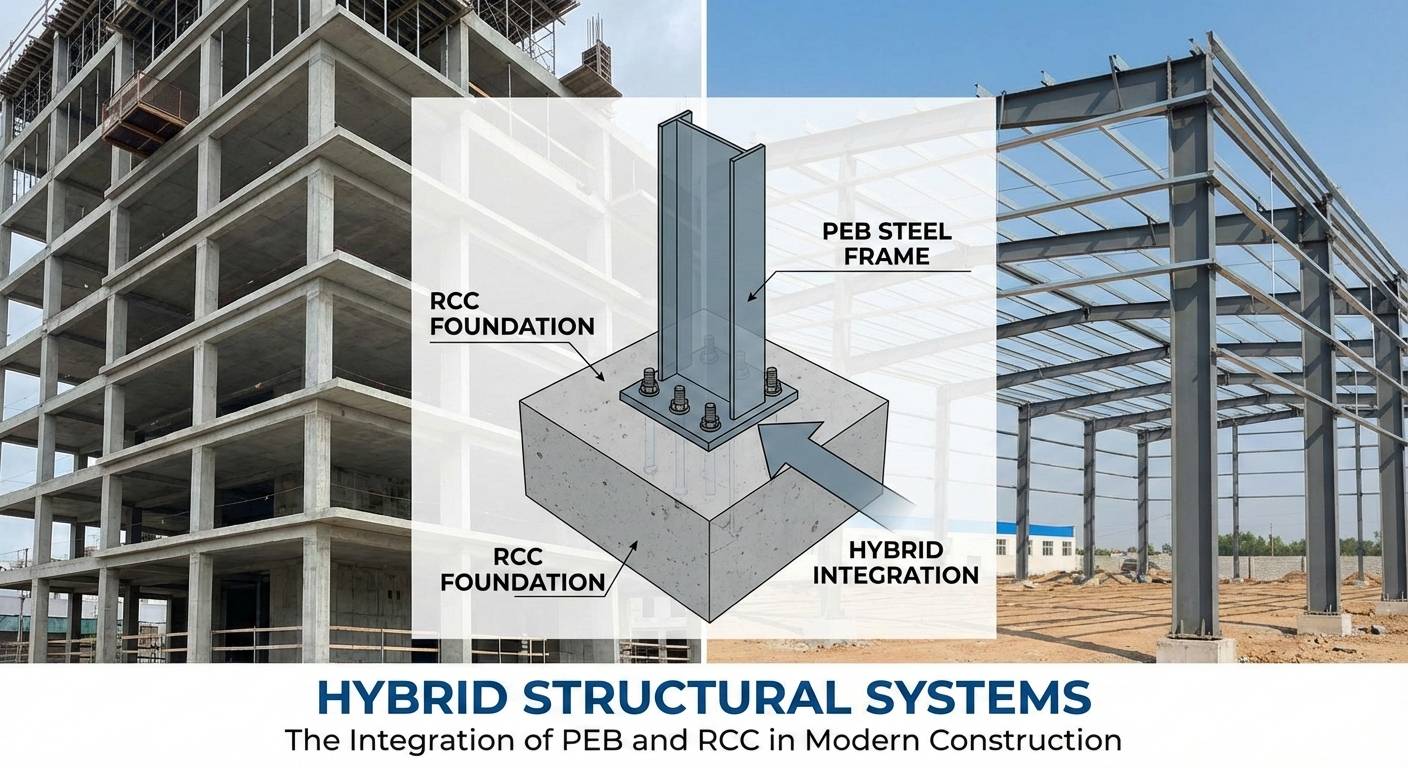

- Evaluate Structural Systems: We assess various structural options (e.g., steel, concrete, hybrid, Pre-Engineered Buildings - PEB) to recommend the most efficient and cost-effective system for your project's specific needs, whether it's an industrial shed or a multi-storey building in Chandigarh.

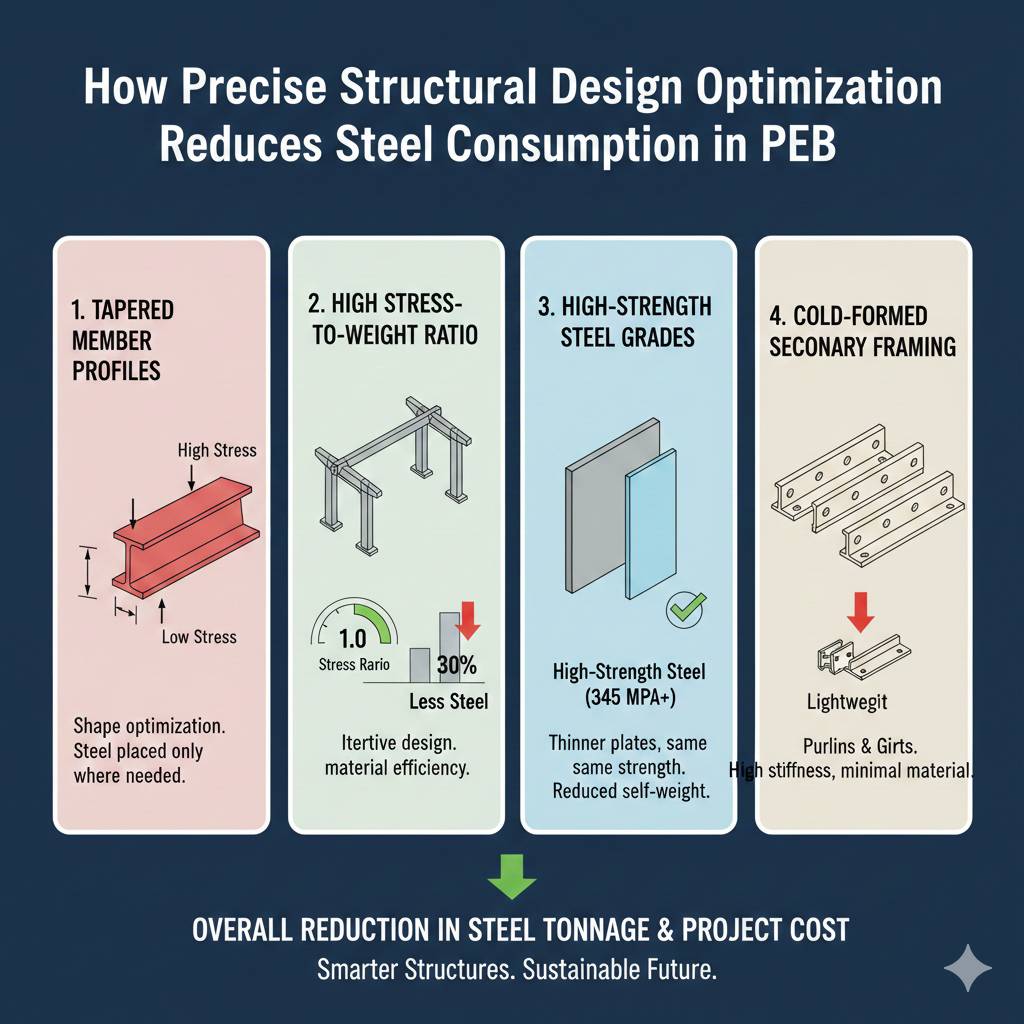

- Precise Member Sizing: Through advanced analysis of loads and stresses, we ensure that every beam, column, and slab is sized precisely. This avoids the common pitfall of over-designing elements out of caution, directly reducing the amount of steel, concrete, or timber required.

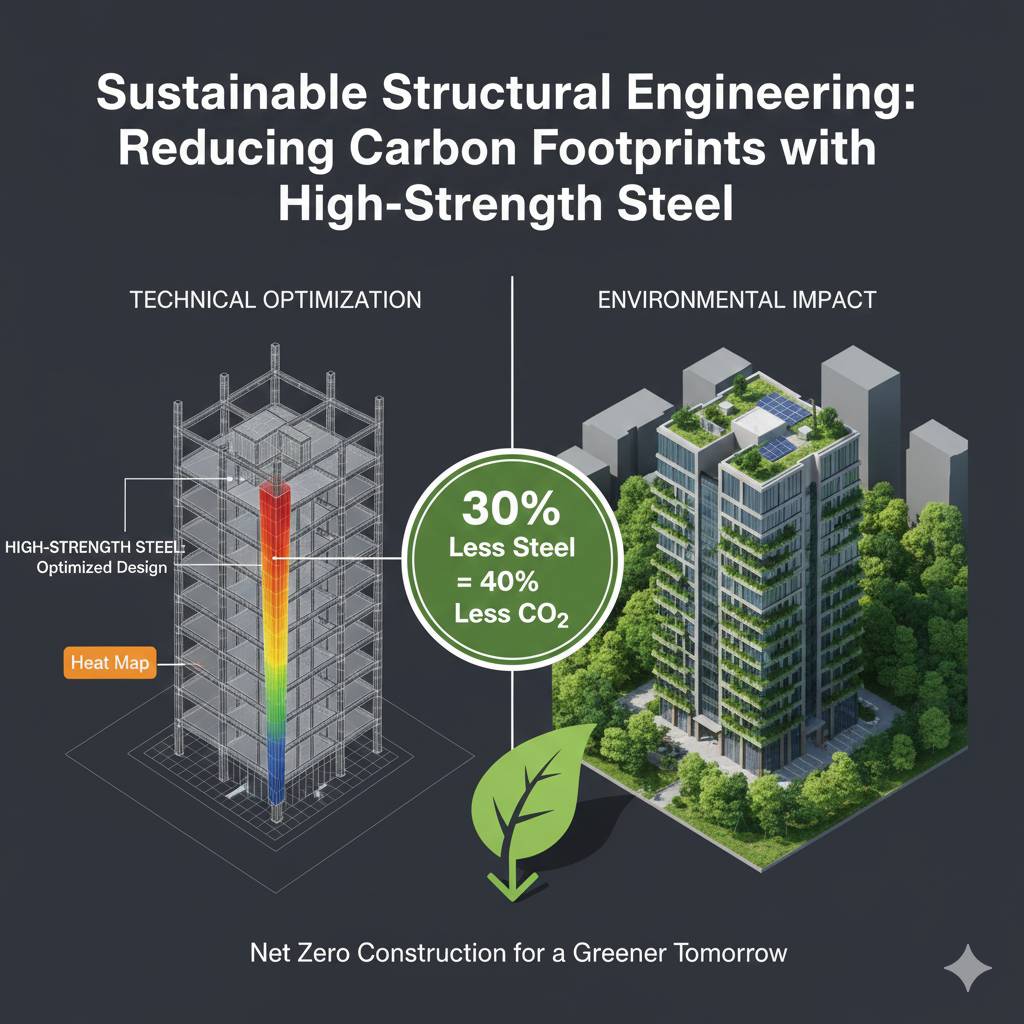

- Innovative Material Use: Our expertise allows us to recommend high-strength steel or other innovative materials that, despite a potentially higher unit cost, significantly reduce the overall material volume, leading to net savings.

- Minimize Waste & Rework: By optimizing designs from the outset, we drastically reduce the potential for ordering excess materials or needing costly field modifications due to structural conflicts, saving both time and money.

2. Significant Foundation Cost Savings

The foundation is often one of the most expensive and critical components of any building, especially on varied terrain. Early structural input from Rakhra Associates is invaluable here:

- Integrated Geotechnical Analysis: Collaborating closely with geotechnical experts from day one, we interpret soil reports to design the most economical and safe foundation system. This could mean opting for shallower foundations, fewer piles, or a more efficient raft design, preventing expensive over-engineering based on generic assumptions.

- Reduced Loads: A lighter, more efficient superstructure, a hallmark of our optimized designs, naturally exerts less load on the ground. This directly reduces the demands – and therefore the cost – of the entire foundation system.

3. Streamlined Construction & Faster Project Delivery

In construction, time is indeed money. An optimized structural design from Rakhra Associates directly leads to faster and smoother project execution:

- Constructability Review: Our engineers identify potential construction challenges during the design phase, proposing solutions that simplify erection, reduce on-site labor hours, and minimize the need for specialized, expensive equipment.

- PEB Integration Expertise: For industrial and large commercial spaces, early consultation often highlights the suitability of Pre-Engineered Building (PEB) systems. Rakhra Associates specializes in PEB designs that offer rapid off-site fabrication and on-site assembly, significantly cutting down construction time and associated overheads.

- Preventing Delays & Reworks: Structural clashes, unforeseen load issues, or design incompatibilities discovered late in the project are major sources of delays and expensive reworks. Our proactive review process catches these issues before they escalate.

4. Enhanced Long-Term Value & Reduced Operational Costs

The "savings" don't end with the initial construction. A meticulously engineered structure offers benefits throughout its entire lifecycle:

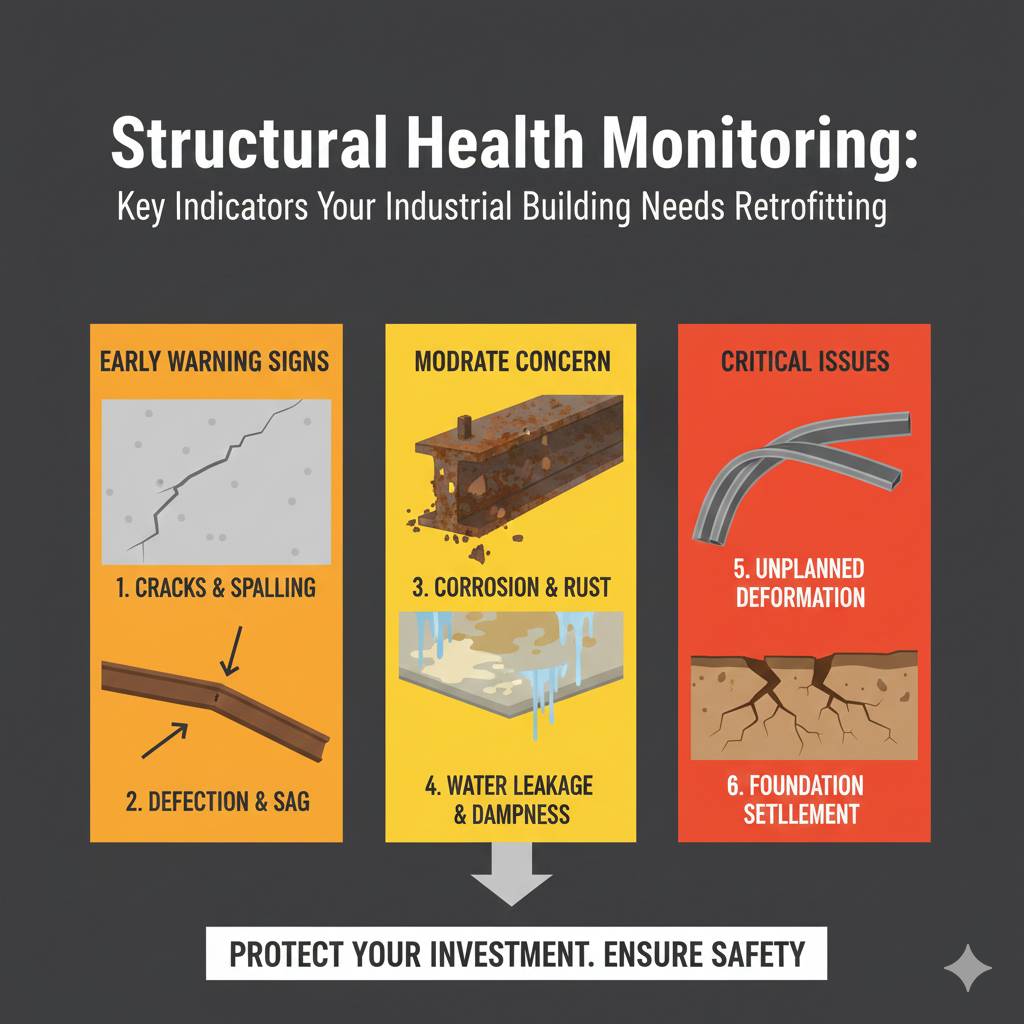

- Durability and Resilience: An optimized structural design ensures your building is robust against environmental factors (wind, seismic activity – especially crucial in regions like Chandigarh) and daily wear, significantly reducing future maintenance and repair costs.

- Future Flexibility: A thoughtfully designed structure provides greater flexibility for future renovations, expansions, or changes in use, avoiding costly structural modifications down the line if your business needs evolve.

5. Comprehensive Risk Mitigation

Ignoring expert structural advice early on is a gamble with your entire investment. Unforeseen structural issues can halt projects, lead to expensive legal disputes, and damage reputations. Engaging Rakhra Associates from the outset provides peace of mind, as we proactively identify and address potential risks, ensuring compliance and safety.

Partner with Rakhra Associates for Smarter Construction

Don't let hidden costs erode your construction budget. By engaging Rakhra Associates for early structural consultation, you're not just hiring an engineer; you're gaining a strategic partner dedicated to maximizing structural integrity while minimizing project costs and timelines. Let us help you build a resilient, efficient, and cost-effective structure that stands the test of time.