Blog

PEB Structures in Industrial Projects: Cost, Speed, and Safety Compared

Introduction: The New Era of Industrial Construction

In today’s competitive industrial landscape, speed, cost-efficiency, and safety are not just desirable—they’re essential. Traditional reinforced concrete structures, though reliable, often struggle to meet the fast-paced demands of modern industries. Enter Pre-Engineered Buildings (PEB) — a revolutionary construction solution redefining how factories, warehouses, and logistics centers are built.

Rakhra Associates, a leading name in structural engineering in Chandigarh, has been at the forefront of implementing PEB systems for industrial and commercial projects, offering clients durability, economy, and speed unmatched by conventional construction.

What Are PEB Structures?

Pre-Engineered Buildings (PEBs) are steel structures fabricated off-site and assembled on location. Every component—from primary framing to roofing and cladding—is designed using advanced software and precision manufacturing.

Key Components Include:

- Primary Frame: Rigid steel columns and rafters.

- Secondary Frame: Purlins, girts, and eave struts.

- Roof & Wall Panels: Made from coated steel sheets for durability.

- Bracing Systems: For lateral stability and seismic resistance.

This system provides flexibility in design while ensuring consistent quality and faster erection times.

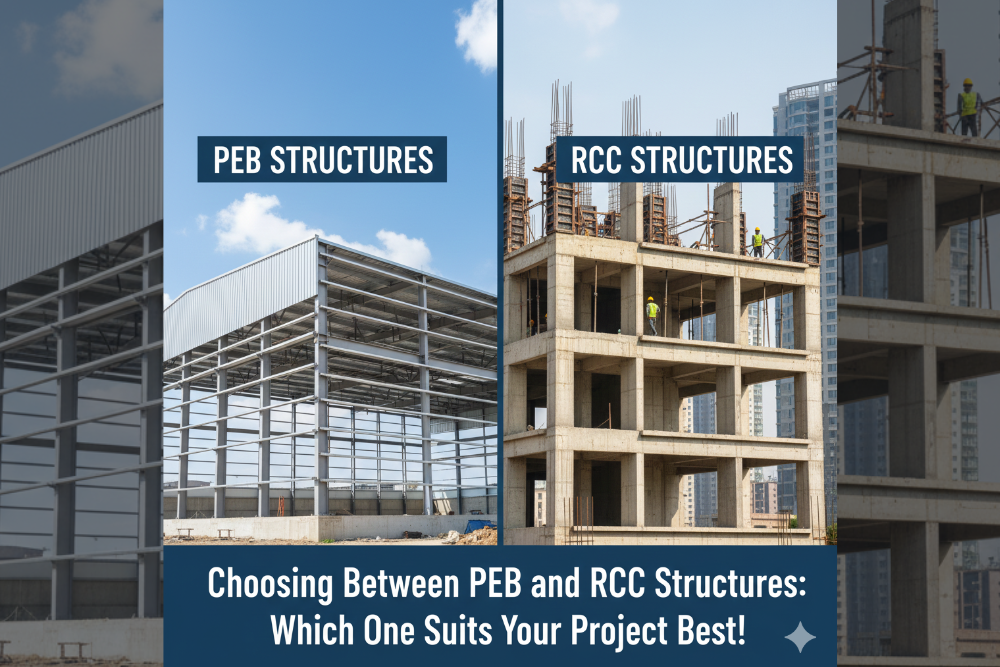

PEB vs. Conventional Construction: A Quick Comparison

| Parameter | PEB Structure | Conventional RCC/Steel Structure |

| Construction Time | 50–60% faster (pre-fabricated) | Slower due to on-site casting and curing |

| Cost Efficiency | 10–20% lower total cost | Higher due to labor and material waste |

| Accuracy | High precision (factory made) | Moderate, depends on site execution |

| Flexibility | Easy to expand or modify | Rigid and difficult to alter |

| Maintenance | Low | Moderate to high |

| Safety | High — engineered for loads and weather | Variable based on construction quality |

PEBs combine the best of engineering precision and field practicality, making them ideal for industrial use.

Advantages of PEB Structures

1. Speed of Construction

Pre-fabrication ensures that while foundations are being laid, superstructure components are already in production.

This parallel workflow cuts project timelines by up to 60%, making it ideal for industrial parks and manufacturing plants where early commissioning is crucial.

2. Cost Efficiency

PEBs minimize waste, labor, and material handling. Components are optimized for:

- Minimal steel usage without compromising strength

- Reduced labor dependency

- Lower foundation costs (due to lightweight design)

On average, PEB projects cost 15–20% less than RCC or conventional steel projects.

3. Superior Structural Safety

Each PEB is designed to withstand:

- High wind loads

- Seismic forces (IS 800:2007 & IS 1893 compliance)

- Fire and corrosion exposure

Rakhra Associates ensures safety by using finite element analysis (FEA) and 3D modeling to predict and manage loads precisely.

4. Design Flexibility

PEBs can accommodate large clear spans up to 100 meters, ideal for:

- Aircraft hangars

- Warehouses

- Industrial workshops

- Logistics hubs

With modular design, expansion becomes effortless — simply add more bays without disrupting operations.

5. Sustainability and Green Construction

Steel, the core of PEBs, is 100% recyclable.

Combined with solar roof integration, rainwater harvesting, and thermal insulation panels, these structures meet green building standards while reducing operational energy consumption.

Applications of PEB Structures in Industrial Projects

PEBs have wide-ranging applications across India’s rapidly growing industrial sector:

- Manufacturing Plants – Quick setup and scalability.

- Warehouses & Cold Storage Units – High volume capacity and energy-efficient design.

- Textile & Automotive Plants – Clear span layouts for process flow optimization.

- Commercial Hubs & Malls – Architectural flexibility with reduced maintenance.

- Logistics Parks – Ideal for large, fast-erecting warehouses.

In Chandigarh’s industrial ecosystem, Rakhra Associates has implemented several PEB-based facilities offering operational and financial advantages to clients.

Structural Design and Analysis in PEB

Advanced Design Tools

Rakhra Associates employs:

- STAAD.Pro for structural analysis

- Tekla Structures for detailing

- AutoCAD for layout precision

- Revit BIM for collaborative modeling

These tools ensure the highest structural accuracy, seamless fabrication, and minimal site errors.

Material Standards

PEBs follow international design codes:

- IS 800:2007 – General Construction in Steel

- MBMA – Metal Building Manufacturers Association Standards

- AISC – American Institute of Steel Construction

Challenges in PEB Implementation

While PEBs offer unmatched advantages, certain challenges exist:

- Initial capital investment in manufacturing setup

- Transportation logistics for large components

- Design limitations for extremely complex architectures

However, these are mitigated by local fabrication, modular design, and digital planning — all part of Rakhra Associates’ integrated project approach.

Case Study: Industrial PEB Project in Punjab

In 2024, Rakhra Associates designed and executed a PEB warehouse project near Mohali, covering over 60,000 sq. ft.

Results:

- Construction completed 40% faster than RCC design

- Cost savings of ₹1.2 crore through optimized steel design

- Zero on-site accidents due to pre-fabricated assembly

This project stands as a benchmark for how smart structural planning drives industrial growth.

Safety Considerations in PEB Design

Safety is non-negotiable in industrial construction.

PEBs incorporate:

- Fire-resistant coatings

- Bracing systems for seismic loads

- Anti-corrosive galvanized coatings

- Wind uplift design for high-speed zones

Rakhra Associates ensures every project complies with NBC 2016, IS 800, and OSHA safety guidelines.

Future of PEB in India

India’s industrial expansion, fueled by Make in India, Atmanirbhar Bharat, and Smart Cities Mission, is driving massive demand for fast and efficient construction.

PEBs are expected to dominate warehousing, logistics, and data center infrastructure due to:

- Modular adaptability

- Sustainable performance

- Low lifecycle cost

According to industry reports, the PEB market in India is growing at 12–15% annually, with Punjab, Haryana, and Chandigarh emerging as key hubs.

FAQs on PEB Structures

Q1. What is the lifespan of a PEB structure?

Typically 50+ years with minimal maintenance due to high-quality coatings and design precision.

Q2. Are PEBs earthquake-resistant?

Yes. PEBs are designed to absorb seismic energy efficiently, making them safer than traditional RCC systems in seismic zones.

Q3. Can PEBs support heavy loads like cranes or machinery?

Absolutely. They can be engineered to support heavy-duty cranes, equipment, and mezzanine floors.

Q4. How are PEBs maintained?

Routine inspection and repainting of exposed steel every 5–7 years ensure longevity.

Q5. Are PEBs suitable for high-temperature regions?

Yes, with proper insulation and ventilation design, they perform well in all climates.

Q6. What makes Rakhra Associates a trusted name in PEB design?

Their engineering precision, use of advanced digital modeling, and adherence to global safety codes ensure world-class results.

Conclusion

PEB structures represent the future of industrial construction in India — combining cost-efficiency, rapid deployment, and uncompromised safety.

For industries seeking faster project turnaround and superior quality, PEBs deliver unbeatable value.

With Rakhra Associates – Structural Engineers in Chandigarh, clients gain access to the best-in-class PEB design, detailing, and implementation services, transforming industrial visions into durable realities.